Compressed air is often referred to as the ‘fourth utility’ and is critical to most manufacturing operations. Facility performance depends upon compressor reliability and efficiency.

Power consumption is a significant cost throughout the life of a compressor, therefore it is important to consider the life cycle cost of a compressed air system when evaluating productivity improvements.

More than 70% of the long term cost of owning an air compressor can be attributed to energy use. Over the life of the compressor this adds up to many times the original investment, yet in many cases much of this energy is wasted through poor part load control.

Permanent Magnet, Variable Frequency technology (PMV) as applied to air compressors is proving to be a game changer providing maximum efficiency and performance while offering remarkable, energy saving performance.

Developed by Kaishan engineers, these revolutionary compressors combine integrated systematic optimisation of the compressor unit with an advanced permanent magnet motor, Kaishan SKY airend and rapid response variable speed drive to achieve outstanding energy efficiency.

These advanced PMV compressors will exactly match output to demand, eliminating high part load energy usage as experienced with conventional fixed speed compressors. With the right PMV compressor for your operation, energy savings as high as 50% are possible.

KAISHAN PMV COMPRESSORS OFFER HUGE ENERGY SAVING ADVANTAGE OVER CONVENTIONAL ROTARY SCREW COMPRESSORS

Kaishan PMV compressors operate at peak efficiency even with 80% reduction in air output. They offer far greater integrated control precision through an advanced PID control algorithm that generates a highly stable supply pressure. By regulating the volume of air output, the compressor maintains maximum efficiency under wide usage demands.

The PMV compressor demonstrates a remarkable energy saving capability over conventional types particularly when under widely fluctuating demands.

Motor angular position sensors are not required, improving both stability and reliability. Torque can be compensated at any angle within 360O to achieve perfect control. Utilisation of bus voltage is greater than 93%, much more than conventional converters.

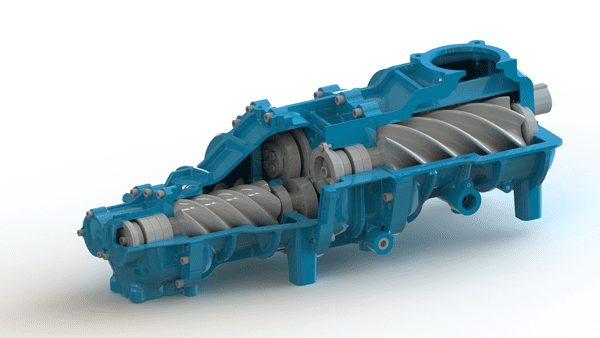

Continual trial and development has created an advanced airend that increases PMV compressor efficiency by more than 20% over earlier models.

Larger Rotor Size

To increase the rotor throughput, the airends in Kaishan PMV compressors are larger than usual. They are built with 5/6 lobes and larger rotor size which reduces the specific power consumption and runs at low speed.

Lower inter-lobe leakage losses

Pressure differences between two neighbouring work chambers is small due to a greater number of lobes. This reduces inter-lobe leakage losses, hence leakage to delivery ratio decreases as the number of lobes increases.

Larger wrap angle & discharge port

A greater number of lobes combined with larger wrap angle ensures multiple rotor contact. This reduces vibrations which minimises noise. Larger discharge ports decrease the discharge velocity and therefore reduce the discharge pressure losses increasing the compressor’s overall efficiency.

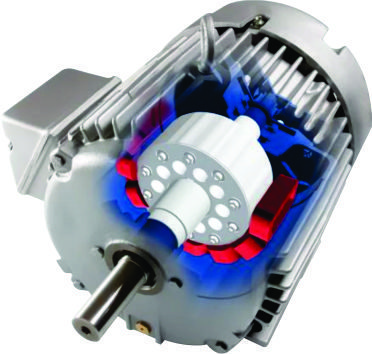

RARE EARTH MAGNET TECHNOLOGY

Rare earth technology gives the permanent magnet motor superior energy efficiency compared to

conventional induction motors. Permanent Magnet synchronous torque motors provide faster acceleration and deceleration, a great advantage in compressor applications as they can rapidly vary output to match application demands.

- Energy efficient over a wide speed range

- Variable speed in constant and changing torque requirements

- Lower routine and long term maintenance

BENEFITS OF PMV AIR COMPRESSOR TECHNOLOGY

- Complete control of air output to meet operating demand

- Lower energy input for required air generation

- Excessive part load energy usage is significantly reduced

- Gradual increase in motor speed eliminates starting spikes and cost penalties

- A steady system pressure is maintained, lowering system stress and overall air demand

- Reduced artificial demand due to lower operating pressures

- Reduced maintenance time and cost

- Significantly lower noise levels

Kaishan Australia’s range of PMV rotary screw compressors combine engineering excellence with the highest quality components into a compact unit to provide maximum output with minimum energy use. These highly advanced air compressors deliver world class efficiency and performance in a heavy duty unit that ensures superior durability and reliability. Precision engineering utilises the latest compressed air technologies to achieve energy standards exceeding international expectations.

Mr Kevin Cao, President of the Kaishan Group of Companies stated that the organisation currently has plant and equipment valued at over USD$2.1b based in multiple plants across the world employing more than 4,500 personnel including over 2,000 trained technicians.

Kaishan Australia supplies its extensive compressed air product range offering truly heavy duty, high quality and premium efficiency machinery for an enormously broad range of applications.

After almost 40 years of success in supporting the Australian compressed air market, Kaishan Australia utilises the world’s best technologies with the ability to customise solutions that provide optimal benefits to its Australian customers.

Kaishan Australia is the Australian division of the Kaishan Group of Companies, one of the largest and most advanced designers and manufacturers of compressed air and gas products in the world.

Kaishan is committed to the continuous development of new compressor technologies and currently produces more than 80,000 rotary and 25,000 reciprocating air compressors annually for applications and installations in the Australian, European, SE Asian, USA, India and Latin American markets with growth globally through partnerships and acquisitions.