PMV - permanent magnet variable speed Rotary Screw Air Compressors

- COMPLETE AIR OUTPUT CONTROL

- LOWER ENERGY INPUT

- GREATLY REDUCED PART LOAD ENERGY USE

- NO STARTING SPIKES AND COST PENALTIES

- STEADY SYSTEM PRESSURE

- OUTSTANDING MOTOR EFFICIENCY

REDUCED - MAINTENANCE TIME AND COST

- SIGNIFICANTLY LOWER NOISE LEVELS

PMV rotary screw air compressors utilise integrated systematic optimisation of an advanced permanent-magnet motor combined with a variable speed drive in either single or 2-Stage variants.

Offers unsurpassed efficiency in industrial air compressors from 15 to 250kW. A model to match the needs of virtually any industry application. World class efficiency in a heavy-duty unit ensuring superior reliability and reduced running costs.

Kaishan Australia offers a premier line of PMV rotary screw compressors, engineered to merge top-tier engineering with premium components in a sleek, compact design. These compressors are designed to maximize output while minimizing energy consumption. Our advanced rotary screw compressors are renowned for their exceptional efficiency and robust performance, making them ideal for heavy-duty applications that demand reliability and durability.

The precision-engineered units leverage cutting-edge compressed air technology to surpass global energy efficiency standards. Kaishan’s innovative approach includes the integration of a high-efficiency permanent magnet motor, the exclusive Kaishan SKY airend, and a responsive variable speed drive. This combination ensures optimal energy savings and performance.

Explore the benefits of our energy-efficient air compressors and discover how Kaishan’s commitment to innovation delivers superior compressed air solutions that are both powerful and sustainable.

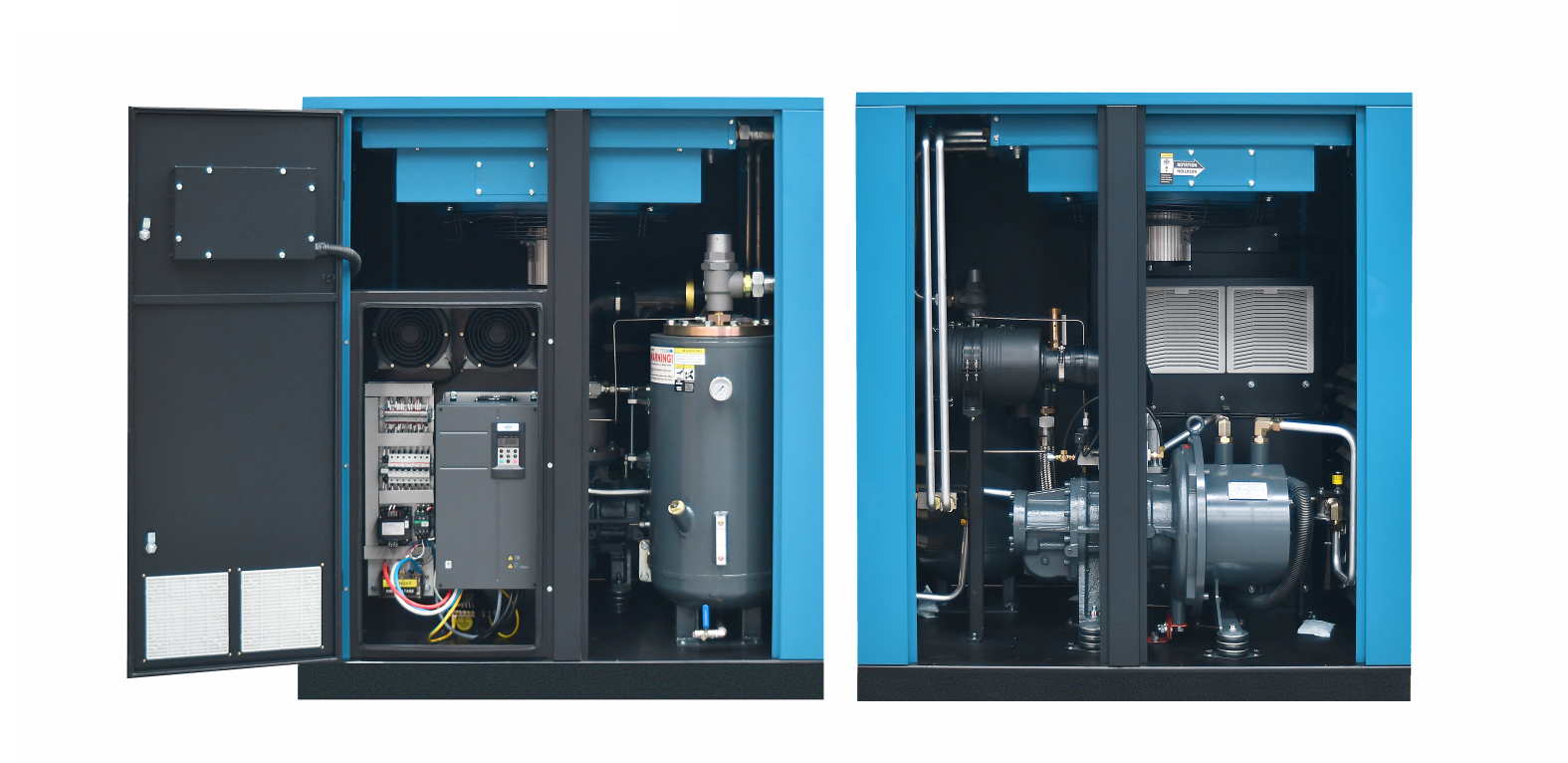

WHAT'S INSIDE THE PMV ROTARY SCREW AIR COMPRESSOR

High Efficiency Drive Motor

DIGITAL

CONTROL

PANEL

Integrated Dryer/Air Filter

Integrated Air Cooling/Cooling Fan

Excellent mechanical pre-separation/reduced direct oil impingement onto separator element

Lower dust contact resulting in lower pressure drop/longer element life/lower energy consumption

Residual oil carryover limited to 3 ppm

Maximum Output with Less Energy Usage

• Asymmetric 5 / 6 rotor profile with 100% SKF bearings and world class

• KAPP Ground rotor technology for tighter clearances efficiency and performance

• Precision machined bell housing to maintain rigid alignment

Integrated air /oil separator incorporating tangengial pre-separation

TEFC High Efficiency, Permanant Magnet drive motor powered through a variable speed drive

IP55 protection against dust and moisture

Class F insulation

No external energy source required to excite the rotating magnetic field improving efficiency

No starting spikes and cost penalties

Oil cooled (15kW to 55kW single stage). All 2-Stage models are air cooled.

Monitors & Controls Key Compressor Functions

• Displays pressure, temperature, motor current, faults

• Phase failure protection

• Service schedule notification

• External monitoring via RS 485 interface

• Shutdown protection

• Sequencing of up to 16 compressors

Sequence up to 16 compressors for maximum efficiency

KEY FEATURES

The PMV Rotary Screw Air Compressors from Kaishan Australia are engineered to deliver unparalleled performance and reliability. At the heart of these state-of-the-art air compressors are several key features designed to meet the demanding needs of various industries. Let’s delve into the standout features that set the PMV series apart.

![]() Smart Control Systems: To complement its robust performance, the PMV Rotary Screw Air Compressors come equipped with smart control systems. These intuitive controls make monitoring and operating the air compressors a breeze. With easy-to-navigate interfaces, users can quickly adjust settings, monitor performance, and identify any potential issues before they become problematic. The smart control systems are designed to optimise the compressor’s operation, ensuring that you get the most out of your investment.

Smart Control Systems: To complement its robust performance, the PMV Rotary Screw Air Compressors come equipped with smart control systems. These intuitive controls make monitoring and operating the air compressors a breeze. With easy-to-navigate interfaces, users can quickly adjust settings, monitor performance, and identify any potential issues before they become problematic. The smart control systems are designed to optimise the compressor’s operation, ensuring that you get the most out of your investment.

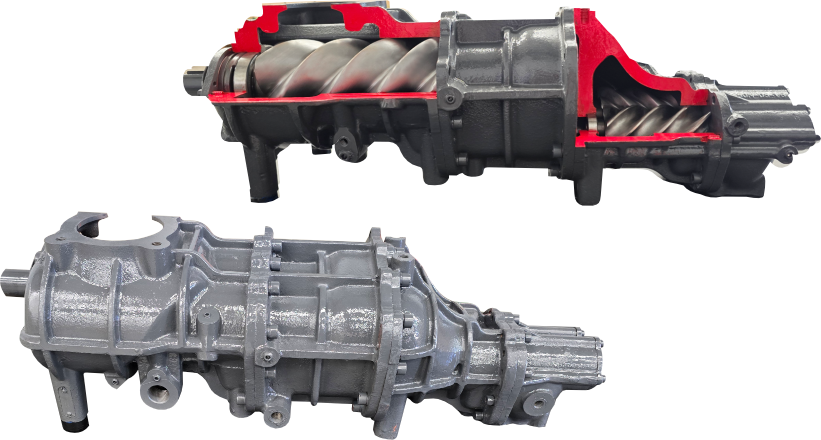

WORLD CLASS ENGINEERING

Continual trial and development has created an advanced airend that increases compressor efficiency by more than 20% over earlier models.

- Larger Rotor Size To increase the rotor throughput, the airends of our PMV compressors are larger than usual. They are built with 5/6 lobes and larger rotor size which reduces the specific power consumption whilst operating at low speed.

- Lower inter-lobe leakage losses Pressure differences between two neighbouring work chambers is small due to a greater number of lobes. This reduces inter-lobe leakage losses, hence leakage to delivery ratio decreases as the number of lobes increases.

- Larger wrap angle & discharge port A greater number of lobes combined with larger wrap angle ensures multiple rotor contact. This reduces vibration which minimises noise. Larger discharge ports decrease the discharge velocity and therefore reduce the discharge pressure losses increasing the compressor’s overall efficiency. ‘

Kaishan PMV Compressors offer HUGE energy saving advantage over conventional rotary screw compressors

Kaishan PMV compressors operate at peak efficiency even with 80% reduced air output. They offer far greater integrated control precision through an advanced PID control algorithm that generates a highly stable supply pressure. By regulating the volume of air output, the compressor maintains maximum efficiency under wide usage demands. The PMV compressor demonstrates a remarkable energy saving capability over conventional types particularly when under widely fluctuating demands. Motor angular position sensors are not required, improving both stability and reliability. Torque can be O compensated at any angle within 360 to achieve perfect control. Utilisation of bus voltage is greater than 93%, much more than conventional converters.

- Complete control of air output to meet operating demand

- Lower energy input for required air generation

- Excessive part load energy usage is significantly reduced

- Gradual increase in motor speed eliminates starting spikes and cost penalties

- A steady system pressure is maintained, lowering system stress and overall air demand

- Reduced artificial demand due to lower operating pressures

- Reduced maintenance time and cost

- Significantly lower noise levels

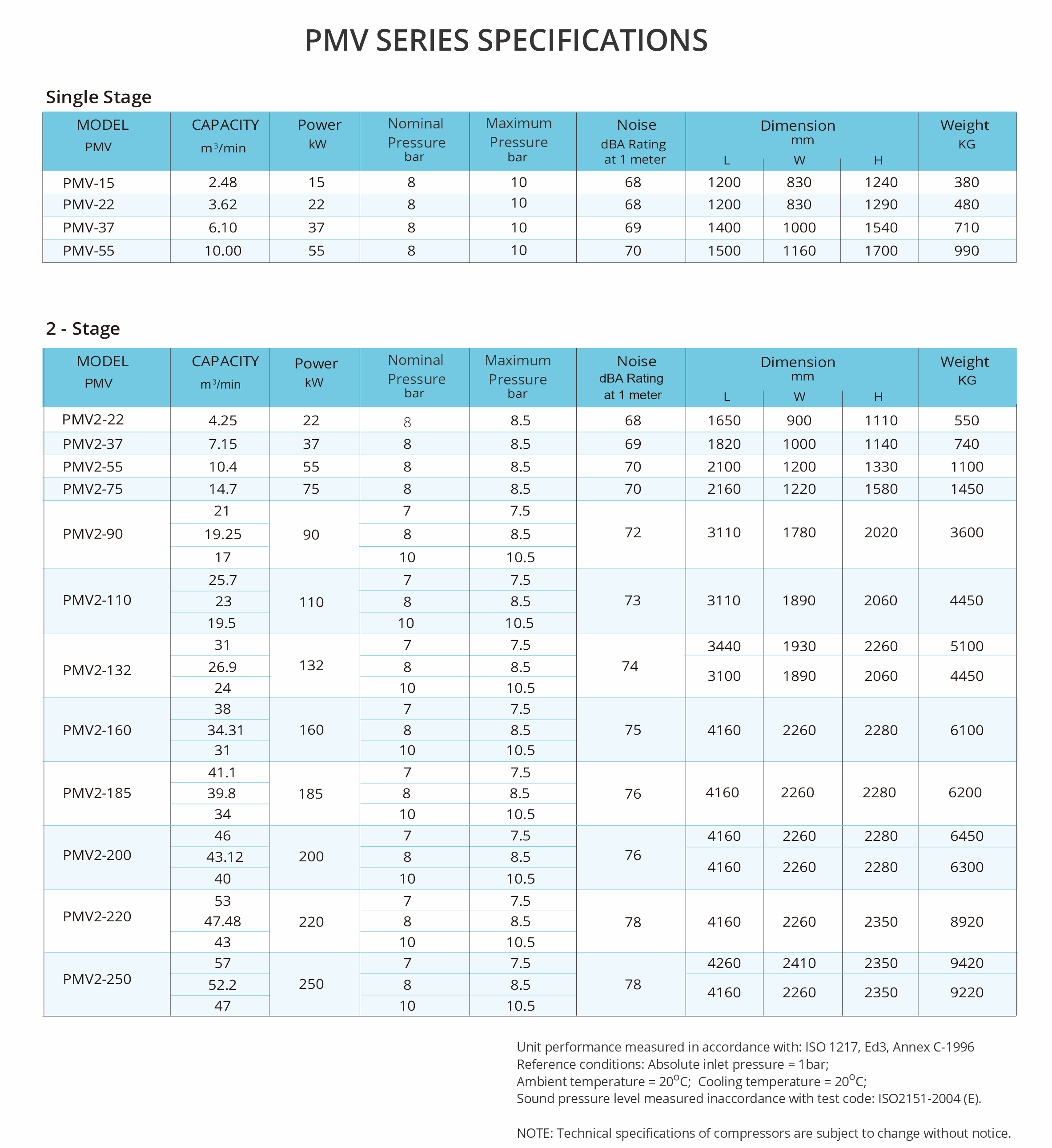

Technical Specifications of PMV Rotary Screw Compressors

When it comes to selecting the right air compressor for your needs, understanding the technical specifications is crucial. The PMV Rotary Screw Air Compressors from Kaishan Australia are designed to meet a wide range of industrial requirements, offering a comprehensive blend of power, efficiency, and reliability. Below, we provide a detailed breakdown of their technical specifications to help you make an informed decision.

The PMV series boasts a diverse range of power ratings, ensuring there’s a model to suit every application. From small industrial units starting at 15 kW, ideal for small-scale operations, to robust models reaching up to 250 kW for heavy industrial use, Kaishan Australia has you covered. This wide power spectrum guarantees that whether your operation is large or small, there’s a PMV compressor that fits the bill.

Pressure capabilities are another critical factor in choosing the right compressor. The PMV series offers a versatile range of pressure settings, from low-pressure models at 5 bar, suitable for specialised applications, up to higher pressure units capable of achieving pressures up to 10 bar. Pressures can be adjusted without the need to replace expensive gears giving you complete air output control. Air flow rates are equally impressive, with the PMV compressors delivering from as low as 2.48 m³/min to a powerful 57 m³/min, ensuring optimal performance tailored to your specific needs.

Understanding the physical specifications of your air compressor is essential for planning your space. The PMV series is designed with a compact footprint in mind, allowing for efficient use of your workspace. Dimensions and weight vary by model, accommodating everything from tight spaces to larger industrial environments. Installation is straightforward, with each unit designed for easy integration into your existing air system. Kaishan Australia also provides comprehensive installation guidance to ensure a seamless setup.

To enhance performance and meet specific air quality requirements, the PMV Rotary Screw Air Compressors are compatible with a wide range of air treatment accessories. From dryers and filters to oil-water separators, Kaishan Australia offers a variety of options to ensure your compressed air is clean, dry, and meets the highest standards of purity for your applications.

Applications and Industries Served

The PMV Rotary Screw Air Compressors from Kaishan Australia are not just machines; they are versatile powerhouses designed to meet the diverse needs of various industries. Their adaptability and efficiency make them an indispensable asset across a wide range of applications, from manufacturing plants to medical facilities. This section delves into the myriad of applications and industries that benefit from the exceptional performance of PMV Rotary Screw Air Compressors.

MANUFACTURING

MINING

WORKSHOP

FOOD AND BEVERAGE

TIMBER

WATER TREATMENT

FABRICATION

Looking after our environment

Energy Efficiency and Environmental Benefits

In today’s environmentally conscious world, energy efficiency is not just a preference but a necessity. Kaishan Australia’s PMV Rotary Screw Air Compressors are at the forefront of this movement, offering a suite of energy-saving features that significantly impact both operational costs and environmental sustainability.

Energy-Saving Features and Impact on Operational Costs

The PMV Rotary Screw Air Compressors are designed with energy efficiency in mind. These compressors utilize advanced technology to ensure that they consume less power while delivering high performance. One of the standout features is the variable speed drive (VSD) technology, which adjusts the motor speed to match the air demand. This means the compressor only uses energy when needed, leading to substantial savings on electricity bills. Additionally, the PMV series boasts a highly efficient airend design, which further reduces energy consumption. By optimising performance and minimising waste, these compressors can significantly lower operational costs for businesses.

Contribution to Environmental Sustainability

Kaishan Australia is committed to reducing the environmental impact of its products. The PMV Rotary Screw Air Compressors contribute to this goal by lowering energy consumption, which in turn reduces the carbon footprint of the operations they support. By using less electricity, these compressors emit fewer greenhouse gases, making them a more sustainable choice for businesses looking to minimise their environmental impact. The efficient design and operation of the PMV series mean that companies do not have to compromise on performance to be eco-friendly.

Compliance with International Energy Efficiency Standards

The PMV Rotary Screw Air Compressors not only meet but exceed international energy efficiency standards. Kaishan Australia ensures that its products are in compliance with global benchmarks for energy efficiency, such as the ISO 50001 standard. This commitment to high standards means that businesses using the PMV series can be confident in their choice, knowing they are utilizing one of the most energy-efficient air compressors on the market. Compliance with these standards also positions businesses well in terms of regulatory requirements and can contribute to achieving certifications that recognize their commitment to energy efficiency and environmental sustainability.

In conclusion, the PMV Rotary Screw Air Compressors from Kaishan Australia offer a powerful combination of energy efficiency, environmental benefits, and compliance with international standards. By choosing these compressors, businesses can enjoy lower operational costs, contribute to a healthier planet, and align with global energy efficiency practices.

Installation and Maintenance

Ensuring your PMV Rotary Screw Air Compressor operates at peak performance starts with proper installation and continues with diligent maintenance. Kaishan Australia is committed to providing you with all the necessary guidance to maximise the lifespan and efficiency of your air compressor. Follow this comprehensive installation and maintenance guide to get the most out of your PMV Rotary Screw Air Compressor.

Step-by-Step Installation Process for Optimal Performance

- Location Selection: Choose a clean, well-ventilated area that is free from excessive dust and moisture. Ensure there is ample space around the compressor for easy access during maintenance.

- Electrical Connection: It is crucial to have a qualified electrician connect your air compressor to the power supply, adhering to all local codes and regulations.

- Air System Connection: Connect the air output to your facility’s air system. Use high-quality pipes and fittings to prevent leaks and ensure efficient operation.

- Foundation Setup: If applicable, ensure the compressor is mounted on a solid foundation to minimise vibration and noise.

- Initial Testing: Before full operation, run the compressor in a test mode to check for any installation errors or immediate issues.

Routine Maintenance Schedule and Tips for Extending Compressor Life

- Daily: Check oil levels, inspect hoses for wear and tear, and monitor the compressor for unusual noises or vibrations.

- Weekly: Clean or replace air filters as needed to ensure optimal air quality and compressor efficiency.

- Monthly: Check and tighten all electrical and mechanical connections to prevent energy loss and potential hazards.

- Annually: Schedule a professional inspection and maintenance service with a Kaishan Australia technician to ensure all components are in top condition.

Troubleshooting Common Issues and How to Address Them

- Loss of Pressure: Check for leaks in the air system and ensure air filters are clean. Replace worn seals or fittings as necessary.

- Overheating: Ensure the compressor is in a well-ventilated area and clean any blocked air intakes. Check and replace the oil if it is degraded.

- Unusual Noise or Vibration: Inspect and tighten loose components. Check the foundation for stability and adjust if necessary.

Benefits of Choosing PMV Rotary Screw Air Compressors

When it comes to selecting the right air compressor for your needs, the PMV Rotary Screw Air Compressors from Kaishan Australia stand out for their exceptional benefits. These state-of-the-art compressors are designed not only to meet but exceed the demands of various industrial applications, offering unparalleled advantages that make them a superior choice. Here are some of the key benefits of choosing PMV Rotary Screw Air Compressors:

One of the most compelling reasons to opt for PMV Rotary Screw Air Compressors is their significantly reduced energy consumption. Thanks to advanced engineering and design, these compressors operate more efficiently, translating into lower operating costs for your business. In an era where energy efficiency is paramount, choosing a PMV compressor can lead to substantial savings on your energy bills, making it an economically smart decision.

Durability and reliability are at the core of PMV Rotary Screw Air Compressors. Engineered to last, these compressors boast a longer lifespan compared to conventional models. What’s more, they require less maintenance, ensuring that your operations run smoothly without frequent downtimes. This not only saves you time but also reduces maintenance costs over the life of the compressor, providing a higher return on investment.

Kaishan’s team of experts is always ready to assist you in making the right choice. Their deep understanding of KRSP Rotary Screw Compressors, combined with insights into various industry requirements, ensures that you select a compressor that matches your operational needs perfectly. Consulting with our specialists can prevent costly mismatches and ensure your investment is sound.