With the world striving to reduce ‘greenhouse emissions’ and generate higher levels of renewable power sources, the Kaishan group is using it’s vast resources to both comply with global expectations and lead the industry in achieving ambitious goals.

The Global Kaishan Group is a world leading compressor design and manufacturing enterprise with over 60 years of history. The company’s main products consist of screw air compressors, refrigerant compressors, screw expanders, gas compressors, and products for environmental engineering and cold-chain industries.

Over the last sixty years, Kaishan has steadily grown to become a significant diversified engineering company, developing high-value equipment for industrial use worldwide. With modern specialized manufacturing facilities around the world, Kaishan is one of the world’s largest manufacturers of compressed air equipment. Combining highly skilled engineering with low-cost manufacturing allows the highest value machinery to be offered to our customers.

Products offering outstanding energy efficiency and reliability are the core of Kaishan’s mission. With a fundamental belief in environmental sustainability, Kaishan produces machinery with the highest energy efficiency to meet the needs of industry now and into the future helping to preserve ever precious energy reserves.

Single and two stage screw compressors that produce more compressed air per unit of power input and expanders that utilize waste heat to produce electricity are fundamental products in the company’s sustainable approach. Throughout the entire manufacturing processes, unused waste materials are rigorously recycled at every stage to maximize the use of raw materials. The end result to customers is that of outstanding energy efficiency and lower operating costs.

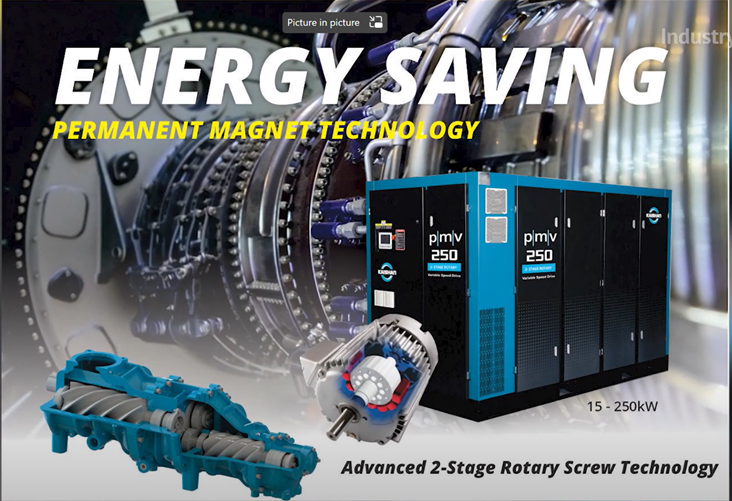

As the locally based arm of the company, Kaishan Australia offer a wide range of industrial rotary screw compressors with power ranging from 4kW to 630kW covering motor power, diesel power, mine shaft explosion-proof screw compressors and double-stage compression screw compressors. Australian customers can now access world class compressor technology and engineering that is fully supported by nation wide service and support.

Leading energy saving technologies

Products offering outstanding energy efficiency and reliability are the core of Kaishan’s mission. A fundamental policy to constantly improve environmental sustainability by producing machinery with the highest energy efficiencies to meet the needs of industry now and into the future ensuring the preservation of precious energy reserves. Kaishan single and two stage screw compressors are designed produce significantly more compressed air per unit of power input.

As a result of the many years of innovation and development, power generated annually by Kaishan’s new energy efficient products now more than covers the energy used to produce them, thus becoming a truly zero-carbon enterprise.

Stringent recycling processes

Throughout the manufacturing processes, all unused waste materials are rigorously recycled at every stage to maximize the use of raw materials.

Kaishan energy-saving and emission-reduction technologies

Kaishan screw expansion is a world-leading low-grade heat to power generation process that utilises direct expansion using residual heat and organic Rankine Cycle (ORC) expansion technology. The process is used in large scale renewable and recylable power sources including geothermal power generation, residual-heat power generation, bio-energy power generation and residual-pressure power generation.

Kaishan’s manufacturing processes are 85% vertically integrated allowing full control of the material supply chain, component costs, and quality. This unique approach to manufacturing provides the ability to respond rapidly to changing market demands bringing new technologies and products to the market quickly and cost-effectively.

Kaishan’s world-class technologies significantly raise the energy efficiency of air compressors and refrigerating compressors, while also reducing the volume of carbon dioxide emission. Screw expansion power-generation technologies can also be applied to new and recyclable energy sources such as geothermal, optical heat and biological energy, thus reducing reliance on fossil energy constituting a global contribution to energy-saving and carbon-emission reduction.

Dedication to the generation of Green energy

Kaishan has clearly developed and defined policies to provide a present and future framework for its organization, establishment and assessment of environmental targets and indicators. Through its patented and evolving screw compressor, power generation technology, Kaishan is undergoing a transition from a major compressor manufacturer into a world leading green energy company. Kaishan’s 85% vertically integrated, technological path has proven to reduce the time and cost of development and manufacturing to enables large-scale development of geothermal resources for broader use of truly green generated energy.

Environmental-protection Measures

Kaishan has always placed environmental protection as an important component of its corporate development strategy. It stresses the production of safe, environmentally friendly, “green” compressor products that meet the high expectations of society and consumers. While supplying customers with high-quality products and services, Kaishan spares no effort in protecting the natural environment whilst achieving sustainable development that will benefit the company, its customers and the global environment.

These measures include

- Compliance with legal and regulatory requirements.

- Prevention of pollution by strengthening environmental management in all aspects of its production and operations including introduction, research, procurement, production and sales.

- Strengthened resource and energy management and reducing the volume of waste through recycling and materials usage.

- Effective control of wastewater, waste gas, and hazardous chemicals to continuously reduce environmental liability and risk.

- Highlight the environmental responsibility of the company’s respective departments, and foster the environmental awareness and ability of all employees.

- Strengthened communication with the government, suppliers, contractors, users and the public to encourage implementation of effective environmental protection by all relevant parties.