Industries around the world are waking up to the potential for savings in compressed air generation costs.

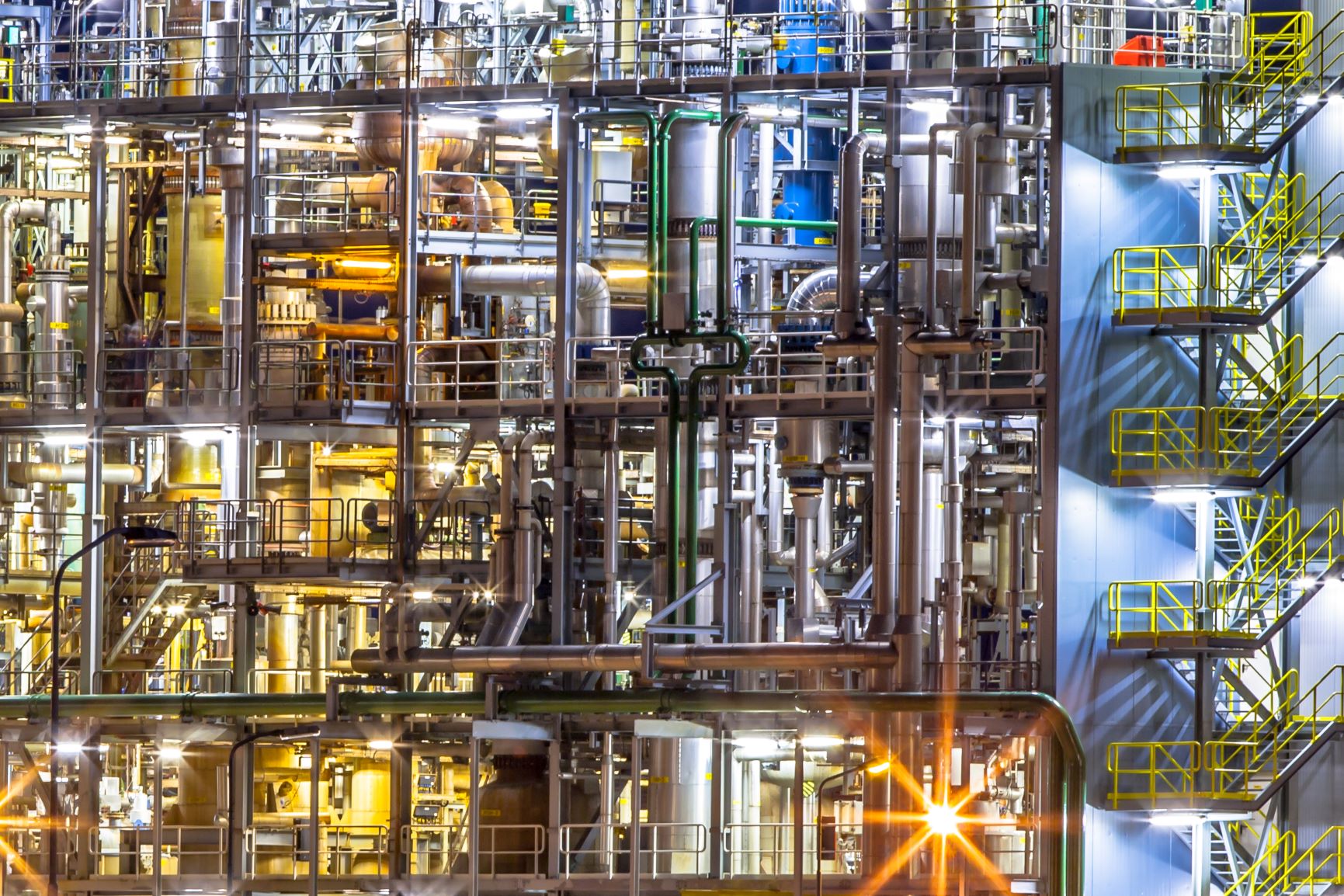

While compressed air generation is vital throughout the world to power production in major industries, it has become a constantly increasing cost factor due to rising energy prices.

This is of particular concern for Australian industry dependent on keeping expense down to remain competitive.

As a result, air compressor manufacturers have been under pressure to provide more cost-efficient and high-performance products and services to offset growing energy costs. But upgrading or replacement of your compressed air plant is not the only answer to curtailing costs.

A low-cost, comprehensive air audit of your current system, particularly those over five years old, can typically expose wasted energy opportunities up to 50%; including air leaks and system set-up faults.

One major company with plants in Australia and New Zealand, guided by a policy of continuous improvement, plus a strong commitment towards minimising all adverse impacts on the environment, sought submissions from several compressed air specialists to conduct a full analysis of its compressed air supply system.

Kaishan Australia (formerly Southern Cross Compressors Australia) was commissioned to undertake a comprehensive audit of the compressed air systems within its Victorian manufacturing plants. The brief was to identify opportunities for improvements in efficiency, reduce operating costs and at the same time further improve the company’s environmental footprint and sustainability.

By eliminating all leaks and other inefficiencies in the system, the audit demonstrated potential annual savings in excess of $300,000 in wasted power over a number of its plants. The same air audit also demonstrated additional potential savings of around $700,000 per annum through the installation of latest technology compressors and ancillary equipment.

The audit clearly identified common power wastage issues such as oversized compressors for specific applications, inefficient or non-existent sequencing between multiple compressors, flow imbalance through air lines, incorrect pipe sizing causing pressure drop, incorrect pressure settings and undersized air receivers.

The review included a complete compressed air audit of both the supply and demand side at sites within Victoria. The supply-side audit involved reviewing the size of the compressors, the installation, filters, dryers and receivers, supply pipe sizes, pressure settings and the method of control. Critical ventilation and maintenance programs were also studied to allow recommendations to be made.

The demand side audit reviewed reticulation piping to point of use, air leaks, incorrect pressure settings, pressure drops and inappropriate uses.

Using the latest technology ultrasonic flow meter, Kaishan technicians were able to determine the exact airflow and usage profile on each airline for each shift on all sites studied. With dramatically varying loads, profiles were then established to identify more suitable, cost-effective equipment to ultimately achieve maximum efficiency. Air leaks on the demand side were identified using an ultrasonic leak detector with every leak tagged, photographed and detailed in a report providing information on leak volumes, corresponding kilowatts wasted and annualised energy costs.

Our knowledge and capability when applied to Australian industry has the potential to revolutionise the way we generate compressed air now and into the future.

Matching the right system to each customer application is critical in meeting production requirements while minimising running costs. Contact us to speak with our technical team about our compressed air audit.