The development of improvements and new technologies in the design and engineering of industrial and compact air compressors, plus the sophistication and efficiency of in-line components ensures that compressed air will continue to be the safe and convenient energy source for industry well into the foreseeable future. Fact is that these advanced compressed air systems are and must continue to be more efficient than alternative forms of power generation.

Recent advances in rotary screw compressors are perhaps the most important, offering machines that are quieter, more efficient and with a much longer service life than superseded models. These advances include permanent magnet variable speed technologies which ensure a far greater output whilst using considerably less energy in turn lowering the costs of operating systems without compromising on performance. When combined with 2-stage rotary screw configuration and variable speed control, these machines offer today’s most energy efficient compressors to suit a broad range of industry applications.

Advances in precision through variable speed control now allow operators to match the output from the compressor with the exact air demand at any given time. This means absolutely no wasted energy throughout any one or multi-process applications. Sophisticated electronic controls can be programmed or manually operated from stop to full capacity depending on demand.

The old piston type (reciprocating) compressors commonly used in workshops and other specialised industries have now been replaced with compact, plug-in, integrated units utilising orbital scroll technology to produce cleaner, quieter air output at much lower running costs and much higher operating efficiency. These machines are also low maintenance and have a far longer working life. Higher energy efficiency, lower maintenance, portability and smaller footprints must be the aim for future advancements in the smaller compressor arena.

The utilisation of these new age compressors is growing globally as industry strives to meet today and tomorrow’s economic and environmental demands. Companies that aim to reduce their environmental impact need to consider this crucial factor.

With continuing advances in the recovery and utilisation of compressed air, there will be a substantial increase in the demand for high efficiency compressors for all types and sizes of industry. In addition, as more new technologies arise from natural gas exploration and contemporary designs from energy-efficient engine drives, a significant focus on emission reduction will benefit from advances in compressed air system design and usage.

Indications are that demand for compressed air will gain in the future for a range of highly practical reasons.

Sustainable energy alternatives:

Compressed air can play an essential role in renewable and sustainable energy alternatives by reducing dependence on traditional forms of energy. Advanced air production, storage and distribution systems can drive new exploration, mining and industrial ventures of the future.

Using compressed air for hybrid car engines:

Another trend that will significantly impact the use of compressed air is the growing interest in improving existing engine systems. By using oil-free technology and more advanced designs, manufacturers can create new ways to improve engine performance.

Significant progress has already been made with the development of air engines. These engines use compressed air as an energy source and reducing emissions by around 30 percent. The benefits of this type of engine are quickly becoming evident as governments and consumers look to reduce their environmental footprint and boost energy efficiency.

Contaminant-free energy supply:

For specific applications including food and beverage processing, pharmaceutical manufacturing, electronics and packaging, chemical and petrochemical processing, air contamination is a critical factor. With limited access to clean fresh air, the provision of a contamination free air source is essential. Already some manufacturers have developed highly efficient, oil free, air-cooled compressors which are used in all kinds of industries where air quality is paramount for the end product and production process. In these critical environments, contamination by even the smallest quantities of oil can result in costly production downtime and product spoilage.

One example of this growing demand is the need for oxygen enriched air in hospital and medical applications as regulatory bodies monitor quality of compressed air systems to ensure patient safety and reduce costs associated with equipment failures and productivity losses.

Global economic growth:

One factor that will significantly impact the use of compressed air is global economic growth. As economies worldwide recover and grow, businesses and consumers will always look for better ways to reduce costs and increase efficiency. By utilising the newest advances and innovations in compressor design, companies can improve process flow with an energy source that reduces waste and saves time and money.

As developing nations become more industrialised, there will continue to be a growing demand for more efficient and specialised compressors. This also means more jobs in the manufacturing, research and development and servicing fields as engineers work to design new types of high-efficiency technologies and technicians are educated to install, commission and service the new systems.

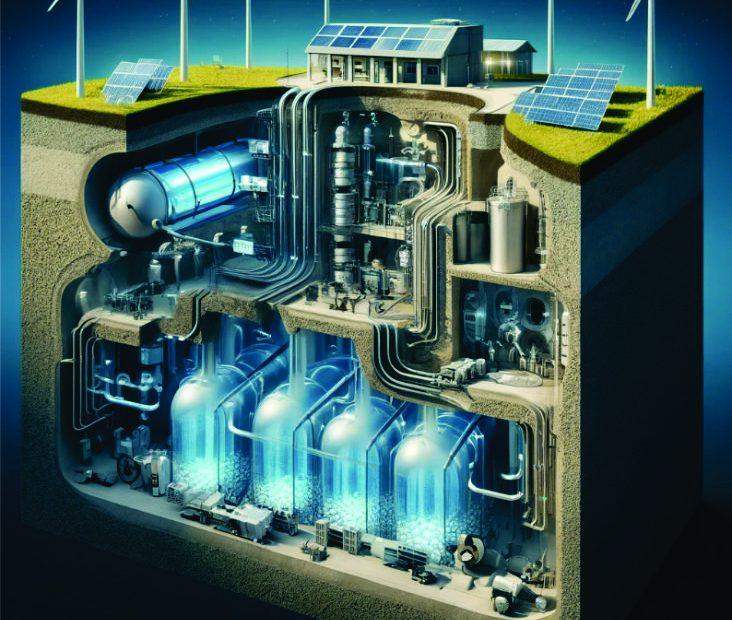

Compressed air energy storage:

Another technology capable of revolutionising our current energy system is compressed-air energy storage (CAES). CAES is a system that stores compressed air underground at extremely high pressure using natural gas or other fossil fuels as an energy source. A turbine generator is used to generate electricity from compressed air when it is needed. As renewables energy prices decrease, CAES could become more competitive, playing play a significant role in reducing our reliance on traditional forms of energy generation.

Conclusion:

With the abilities to reduce greenhouse gas emissions, save money, and improve efficiency, compressed air technology is sure to have a significant impact on the world economy. Businesses and consumers will need to adapt over the coming years as we transition to more sustainable energy sources. Several factors will influence the demand for compressed air in the future. These include global economic growth, the increased need for energy efficiency, and the trend toward more environmentally friendly technologies. Compressors will need to continue to develop to meet the growing demands of businesses and their applications in the years to come.

AI applied to compressor development

Applying AI intelligence to the advancement of air compressors and efficiency of systems could greatly assist in improvements to industrial workflows, productivity and profitability. AI technology can be utilised to help create new age air compressors that can learn from historical data and use it to make critical decisions with little to no human intervention. These intuitive decisions could include:

Fault prediction and detection to prevent shutdowns and expensive repairs.

Advanced AI-driven air compressor management systems could micro-manage output to meet expected demand.

Machine learning algorithms to pick up the early signs of compressor efficiency degradation to optimize servicing.

Kaishan Compressors is at the global forefront of compressed air generation and application technology. Through the company’s R&D, design and manufacturing facilities around the world, Kaishan will always deliver the latest energy efficient, high performance compressors and system components to suit every application.