krof OIL-FREE ROTARY SCREW AIR COMPRESSORS

AIR COOLED

With a Kaishan Oil-Free Rotary Screw Air Compressors, you have the peace of mind that only the highest purity of compressed air is reaching your product.

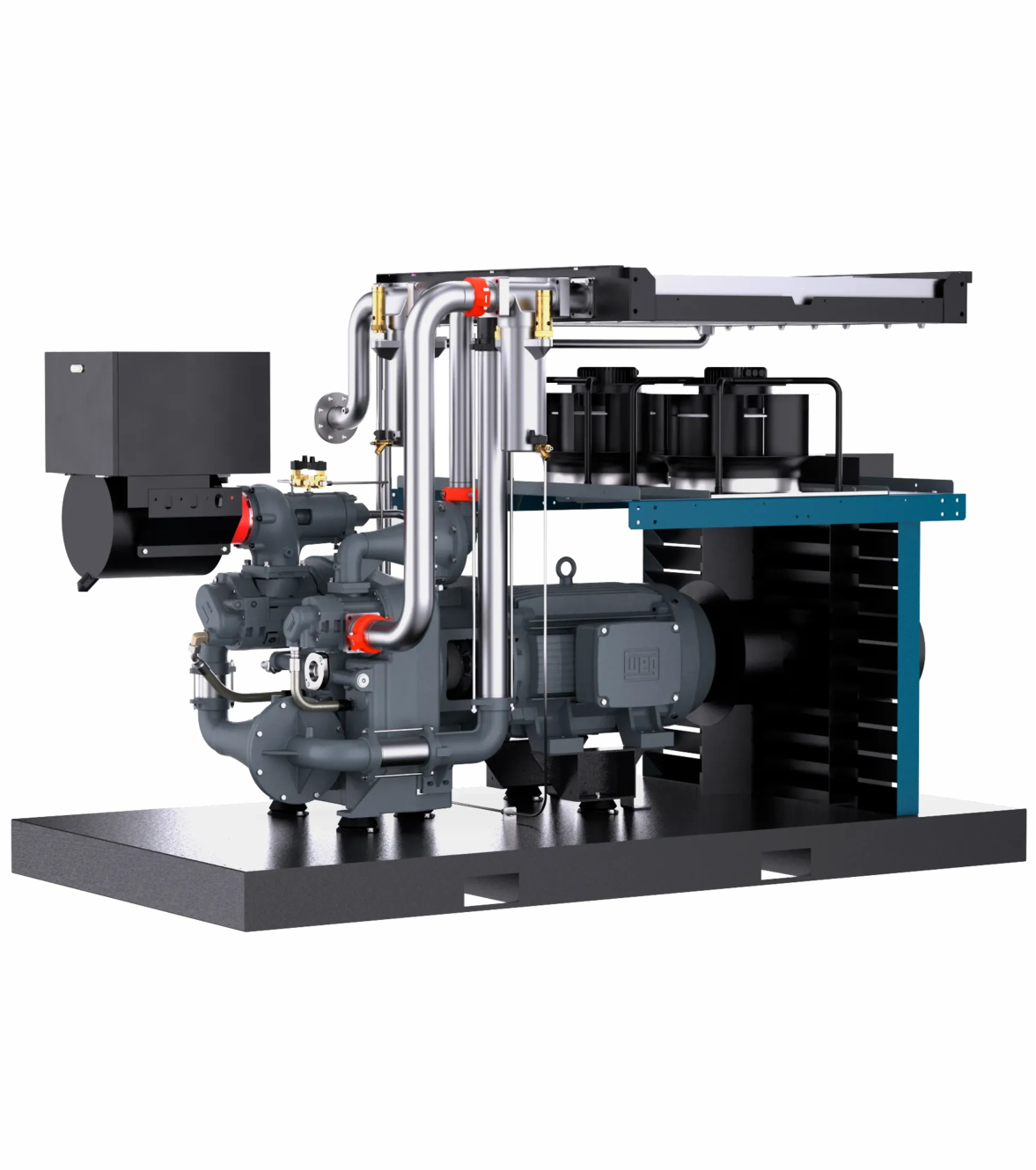

Discover the KROF Oil-Free Rotary Screw Air Compressors by Kaishan Australia

Kaishan Australia proudly introduces the KROF Oil Free Rotary Screw Air Compressor (Air Cooled) – a testament to our unwavering commitment to delivering high-quality, oil-free compressed air solutions. In industries where air purity is not just a requirement but a critical component of operational success, the need for reliable, oil-free technology cannot be overstated. Recognizing this, Kaishan Australia has meticulously developed the KROF series, which stands as a beacon of innovation in the air compressor market.

The significance of oil-free technology extends beyond just meeting regulatory standards; it is about ensuring the integrity of production processes and safeguarding the quality of end products. This is where the KROF series shines, offering unparalleled air purity that meets the rigorous demands of industries such as pharmaceuticals, food and beverage, electronics, and more.

At the heart of the KROF series is an innovative design that sets new standards in efficiency, reliability, and environmental sustainability. Engineered with precision and built to perform, the KROF Oil Free Rotary Screw Air Compressor (Air Cooled) is a symbol of Kaishan Australia’s dedication to excellence and our commitment to supporting industries in achieving their operational objectives while minimizing their environmental footprint.

WHAT'S INSIDE

Hydraulically Control Inlet Valve

Inlet Filter Ducting

Integrated Pulsation Dampeners

Oil Free Air End

Motor

Controls

Cooling Fans

Precooler/intercooler

• Quicker response to system changes

• Lower starting inrush current

• Control independent of operating pressure• Reliable, robust design

• High flow / low pressure drop

• Clean fresh air

• Noise reduction

• Minimise restriction

• Industry leading dBA

• Reduces pressure spikes

• Laminar flow

• Integrated oil distribution lines•

Integrated motor adapter

• Proprietary rotor profile

• PTFE coating on compression elements

• Seal design ensures zero oil in compressed air

• Pressure versatility

• Design life for expected for 5+ years (vs 2 years in the industry)

• Integrated oil pump

• IEC TEFC IE3 Premium Efficiency – IP55 protects against dust, chemicals and humidity

• Flexible Direct coupled

• Integral motor adapter for guaranteed alignment MEPS 2 compliant

• Critical operating parameters monitored and controlled for safe operation

• Networking capable of 16 machines

• Multi-lingual capabilities

• Rugged and robust – UV protected

• Alarms and maintenance reminders

• Aerospace grade Polycarbonate

• Dynamically balanced• Extremely Efficient

• Modular designed integrated motor

• High static pressure capability

• Precooler reduces thermal stress load

• Highly efficient robust 2 stage cooling

• Approach temperatures under 15 degrees

KEY FEATURES

The Kaishan Australia KROF Oil-Free Rotary Screw Air Compressors (Air Cooled) stands at the forefront of innovation, offering a suite of features and benefits designed to meet the rigorous demands of modern industries. At the heart of its design is the commitment to providing a contamination-free air supply, a critical requirement for a wide range of applications where air purity is paramount. Below, we delve into the key features and benefits that set the KROF apart from its competitors.

The KROF’s oil-free operation is its standout feature, ensuring that the air produced is free from oil contamination. This is crucial for industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where air purity directly impacts product quality and safety. By eliminating oil in the compression process, the KROF guarantees a 100% contamination-free air supply, meeting the highest standards of air purity.

In today’s energy-conscious world, the KROF shines with its energy-saving features designed to reduce operational costs while boosting efficiency. Its innovative design minimizes energy consumption, allowing businesses to achieve significant savings on their energy bills. This efficiency does not come at the expense of performance; the KROF delivers optimal output while ensuring lower energy use, making it an environmentally friendly and cost-effective solution for any operation.

The air-cooled design of the KROF, coupled with its fewer moving parts, translates into lower maintenance requirements. This not only reduces downtime but also extends the lifespan of the compressor, ensuring reliable performance year after year. The air-cooled system efficiently manages the compressor’s temperature, reducing the wear and tear on components and minimizing the need for frequent maintenance checks. This feature is particularly beneficial for businesses looking to maximize productivity and minimize operational disruptions.

OIL-FREE ROTARY SCREW COMPRESSORS TECHNOLOGY

At the heart of Kaishan Australia’s KROF Oil-Free Rotary Screw Air Compressor (Air Cooled) lies our pioneering oil-free screw technology. This advanced system is meticulously engineered to deliver clean, contaminant-free air, a critical requirement for a wide range of industries where air purity is paramount. Unlike traditional oil-lubricated compressors, our oil-free design ensures that the air produced is free from oil aerosols and vapors, eliminating the risk of contamination and ensuring the highest standards of air quality.

The significance of oil-free technology cannot be overstated, especially when compared to oil-lubricated systems. Oil-lubricated compressors, while common, carry the inherent risk of oil carryover, which can contaminate the compressed air and, consequently, the end product. This not only compromises quality but can also lead to costly rework or product spoilage. Furthermore, the environmental impact of disposing of oil-laden condensate is a concern, necessitating additional filtration equipment to meet regulatory standards. In contrast, our oil-free compressors eliminate these issues, offering a cleaner, more sustainable solution that reduces both operational risks and environmental footprint.

Moreover, the reliability and longevity of our oil-free design are unparalleled. By eliminating oil from the compression process, we also remove the risk of oil-related wear and tear, leading to a longer lifespan for the compressor and reduced maintenance requirements. This not only ensures a consistent supply of high-quality air over the compressor’s lifecycle but also translates to significant cost savings in terms of reduced downtime and lower maintenance expenses.

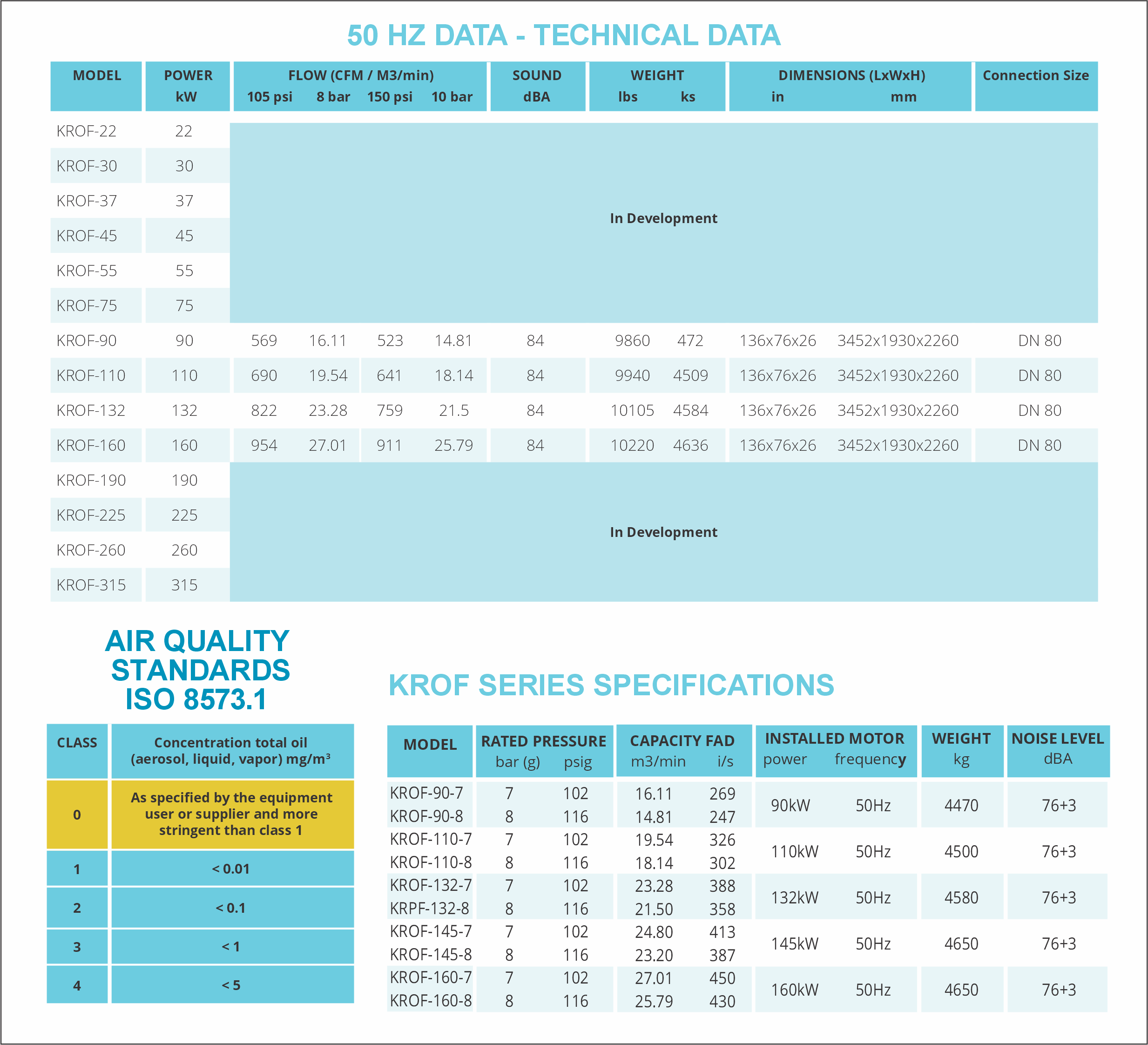

Technical Specifications of KROF Oil-Free Rotary Screw Compressors

The Kaishan Australia KROF Oil Free Rotary Screw Air Compressor (Air Cooled) is engineered to meet the highest standards of performance and reliability. Below are the detailed technical specifications designed to assist in your facility planning and installation processes.

- The KROF series offers a comprehensive power range to suit various industrial requirements, ensuring optimal performance for any application.

- Our compressors are available in multiple pressure ratings to accommodate diverse operational needs, providing flexibility and efficiency in all types of industrial environments.

- The KROF series is designed to deliver exceptional flow capacity, ensuring a consistent and reliable air supply for your operations.

- Unlike traditional water-cooled systems, the air-cooled design of the KROF series offers significant advantages, including reduced maintenance costs, elimination of water usage, and enhanced system reliability. This innovative cooling approach ensures optimal performance even in the most demanding conditions.

- The KROF series is engineered to operate quietly, minimizing noise pollution and creating a more pleasant working environment. Detailed noise level data is available to assist in compliance with workplace regulations and standards.

- Compact design and strategic engineering have resulted in a compressor that is both space-efficient and easy to integrate into existing systems. Detailed dimensions and weight information facilitate smooth installation and integration processes.

Applications and Industries Served for the krof Oil-Free Rotary Screw Compressor

The Kaishan Australia KROF Oil Free Rotary Screw Air Compressor (Air Cooled) is engineered to serve a wide array of industries that demand the highest quality of oil-free compressed air. Our cutting-edge technology ensures that businesses in critical sectors can operate efficiently, safely, and in compliance with stringent industry standards. Below, we explore the diverse applications and industries that benefit from our KROF series compressors.

MANUFACTURING

MINING

WORKSHOP

FOOD AND BEVERAGE

TIMBER

WATER TREATMENT

FABRICATION

Looking after our environment

Energy Efficiency and Environmental Impact

The Kaishan Australia KROF Oil Free Rotary Screw Air Compressor (Air Cooled) stands at the forefront of energy efficiency and environmental stewardship. Our commitment to innovation and sustainability is evident in the design and operation of the KROF series, which significantly reduces energy consumption and minimizes environmental impact.

Reducing Energy Consumption Through Innovation

The KROF series is engineered with cutting-edge design features that enhance energy efficiency. These compressors utilize state-of-the-art air end design, optimized for oil-free operation, which reduces friction and energy loss. The result is a system that delivers high performance with lower energy requirements, translating into significant cost savings for businesses over time. Additionally, the air-cooled system is designed to maximize heat dissipation, further improving efficiency and reducing the need for additional cooling resources.

Environmental Benefits of Oil-Free Compressors

Choosing an oil-free compressor like the KROF series not only benefits your operations but also the environment. By eliminating oil in the compression process, there is no risk of oil contamination in the air supply or the surrounding environment. This leads to cleaner air and reduces the need for oil waste disposal, thereby lowering your company’s carbon footprint. The absence of oil also means there are fewer consumables and less maintenance waste, contributing to a more sustainable operation.

Energy Rebates and Incentives

Investing in energy-efficient technologies like the KROF Oil Free Rotary Screw Air Compressor can qualify businesses for various energy rebates and incentives. Many governments and energy providers offer financial incentives to encourage the adoption of green technologies, recognizing their role in reducing overall energy consumption and promoting environmental sustainability. These incentives can significantly offset the initial investment in energy-efficient equipment, making it a financially viable option for businesses committed to sustainability.

Installation and Maintenance

Ensuring your Kaishan Australia KROF Oil Free Rotary Screw Air Compressor (Air Cooled) operates at peak efficiency starts with proper installation and continues with diligent maintenance. This guide provides a comprehensive overview of the installation process, maintenance schedule, and troubleshooting tips to help you maximize the performance and lifespan of your compressor.

Site Preparation and Requirements:

- Location: Choose a well-ventilated area with enough space around the compressor for easy access during maintenance. The site should be free of dust and contaminants.

- Foundation: Ensure the foundation is level and capable of supporting the weight of the compressor. Use vibration isolators to reduce noise and vibration.

- Power Supply: Verify that the electrical supply matches the compressor’s requirements. A stable power source is crucial for efficient operation.

- Air System Connection: Connect the compressor to your air system using high-quality pipes. Ensure all connections are secure to prevent leaks.

Maintenance Tips and Schedules

To ensure your compressor operates efficiently and has a long service life, adhere to the following maintenance schedule:

- Daily: Check for any leaks or unusual noises. Monitor system pressure and temperature.

- Monthly: Inspect and clean air filters as needed. Check all hoses and connections for wear and tear.

- Quarterly: Change the oil (if applicable), replace air filters, and inspect the drive belt’s condition.

- Annually: Perform a comprehensive inspection of the entire system. This includes checking the motor, electrical connections, and all moving parts for wear.

Trouble Shooting Common Issues

- Reduced Air Output: Check for clogged air filters or leaks in the air system.

- Unusual Noise or Vibration: Inspect the foundation for stability and check if the vibration isolators need replacement.

- Overheating: Ensure the compressor is in a well-ventilated area and check for blocked cooling vents.