krsa single stage low pressure rotary screw air Compressor

55kW – 250kW AIR COMPRESSOR

- Patented SKY Single Stage Airend

- Reduced internal losses

- High efficiency and performance

- Substantially lower energy costs

- Extended bearing life

- High efficiency TEFC LV, drive motor

- Longer bearing life, quieter operation

- Integrated micro-processor

Kaishan Compressors Australia is renowned as a premier provider of industrial air solutions, offering a wide range of high-quality, durable, and efficient air compressors designed to meet the diverse needs of various industries. At the heart of our product lineup is the KRSA single stage low pressure rotary screw air compressor, a testament to our commitment to innovation, reliability, and performance.

The KRSA model is specifically engineered to deliver exceptional performance and reliability, setting a new standard in the low pressure air compressor market. Its design and construction reflect our deep understanding of the demands of industrial applications, ensuring that it not only meets but exceeds the expectations of our clients. The KRSA’s standout features include its robustness, energy efficiency, and the ability to provide consistent, high-quality compressed air, making it an indispensable tool for businesses looking to optimize their operations.

Kaishan KRSA series low pressure rotary screw air compressors are engineered to meet the specific demands of industries such as textile, cement, glass, and pneumatic conveyance. These compressors are ideal for applications where the required operating pressure ranges between 2 to 5 bar, significantly reducing energy consumption compared to standard 7 bar compressors.

WHAT'S INSIDE

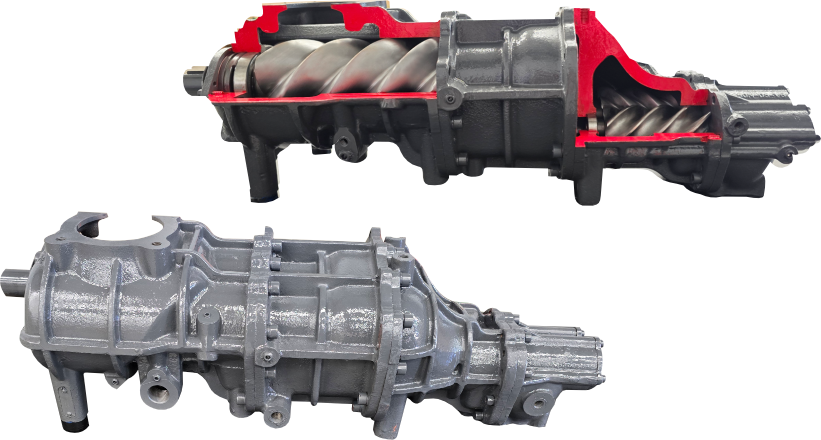

'SKY' Series Airend

Triple Discharge Bearings (45kW and above)

Advanced Digital Control Panel

Centrifugal Cooling Fans

Single Pass Oil and After Coolers

Integrated Dryer/Air Filter

Ultra Web Air Intake Filters

Three Stage Tangential Oil Separation

Kaishan Synthetic Lubricants

- Maximum output with less energy usage.

- Asymmetric 5/6 rotor profile with SKF bearings.

- KAPP grinder rotor technology for tighter clearances with world class efficiency and performance.

- Precision machined bell housing to maintain rigid alignment.

Asymmetric 5/6 rotor profile

KAPP ground rotor technology for tighter clearances and improved lubrication

Low noise and vibration

SKF bearings

- Ease of use due to mimic diagram and temperature readout.

- Selective readout of operation and maintenance parameters provided.

- Safety shutdown feature included.

- Automatic Start/Stop operation over 24 hour period with Lead/Lag sequencing of multiple compressors.

- Auto Dual Control: If there is no air demand during the pre-set time delay, the compressor shuts down the drive motor. The controller will restart the motor only when pressure falls below the pre-selected pressure levels. Integrated with IoT technology which allows remote monitoring and control over local or web networks.

- Monitors and controls key compressor functions.

- Protection against phase sequence.

- Provides service schedule alarm.

- External monitoring via RS 485 interface.

- Increased cooling efficiency Even air flow across the cooler face.

- Cooling air bypasses main compressor compartment resulting in minimal internal dust buildup.

- Long life/ easily accessible.

- Minimises thermal stress.

- Cooler designed for 50 C ambient temperature.

- Low oil carryover.

- Low cooling air velocity reduces dust buildup.

Eliminates failures/Reduces downtime

- Increased Filtration efficiency.

- Full airflow, low restriction.

- Deep bed media ensures excellent dust capture

- Increases free air delivery for further energy and running cost savings

- Lower pressure drop / lower absorbed power.

- Excellent mechanical pre-separation / reduced direct oil impingement onto separator element.

- Lower dust contact resulting in lower pressure drop / longer element life / lower energy consumption.

- Residual oil carryover limited to 1-3 ppm.

Minimum Pressure Drop / Increased Output

- Laminar flow inlet valve results in lower pressure drop through the intake, increasing output and saving energy.

- Lower pressure drop / lower absorbed power.

- High efficiency, TEFC, LV induction drive motors,

- Ip55 rating and IE3/IE4 premium efficiency rating. F class insulation. Direct coupling ensures longer bearing life. Ease of maintenance is assured with grease refill port. ‘No Load Start’ protection is provided.

- Does not cause varnishing during operation.

- High viscosity and high flashpoint.

- Very low carryover.

- Typical 8000 hour service life.

KEY FEATURES & BENEFITS

The Kaishan Compressors Australia KRSA Single Stage Low Pressure Rotary Screw Air Compressor is engineered with cutting-edge technology to deliver unparalleled performance and efficiency. Among its standout features and benefits are:

WORLD CLASS ENGINEERING

PATENTED ‘SKY’ SINGLE STAGE AIREND

Continual trial and development has created an advanced airend that increases compressor efficiency by more than 20% over earlier models.

- Larger Rotor Size To increase the rotor throughput, the airends of our PMV compressors are larger than usual. They are built with 5/6 lobes and larger rotor size which reduces the specific power consumption whilst operating at low speed.

- Lower inter-lobe leakage losses Pressure differences between two neighbouring work chambers is small due to a greater number of lobes. This reduces inter-lobe leakage losses, hence leakage to delivery ratio decreases as the number of lobes increases.

- Larger wrap angle & discharge port A greater number of lobes combined with larger wrap angle ensures multiple rotor contact. This reduces vibration which minimises noise. Larger discharge ports decrease the discharge velocity and therefore reduce the discharge pressure losses increasing the compressor’s overall efficiency. ‘

Kaishan KRSA compressors are built to be compatible with the optional VFD feature. KRSA Variable Speed Air Compressors provide maximum efficiency with consistent operation. Unlike conventional ‘Auto-dual’ and ‘Load/No load’ control modes, KRSA VFD modulates the speed of the drive motor in response to system demand. This results in greater energy saving compared to a fixed speed compressor. The VFD feature greatly reduces the starting power surge of the motor. A constant pressure delivery extends the life of valves.

- Industry renowned VFD units are used in KRSA series compressor packages.

- Compact VFD design allows a smaller footprint.

- Accurately measures key functions of the unit.

- Maintenance free operation.

- Minimises starting current peak loads.

- Performs at extremely low sound level.

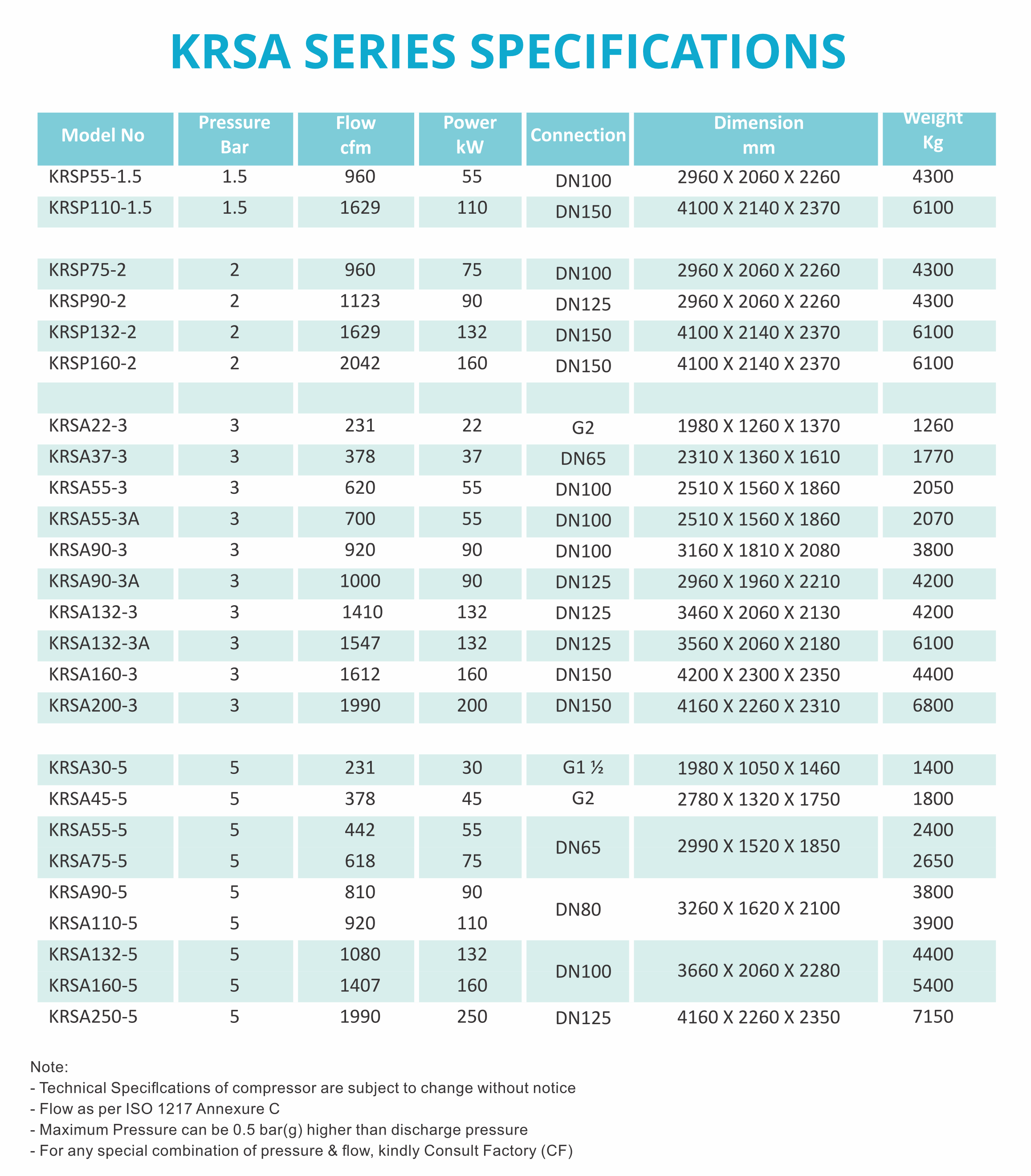

Technical Specifications of krsa single stage low pressure Rotary Screw Compressors

The KRSA Single Stage Low Pressure Rotary Screw Air Compressor from Kaishan Compressors Australia is engineered to meet the diverse needs of modern industries, offering a blend of performance, reliability, and efficiency. Below is a detailed breakdown of its technical specifications, designed to provide you with a comprehensive understanding of its capabilities and compatibility with various applications and environments.

- Capacity: The KRSA series is available in a wide range of capacities, ensuring there is a model to meet your specific air flow requirements. Capacities range from low to high cubic feet per minute (CFM), accommodating small to large-scale operations.

- Pressure Range: Tailored to applications requiring a lower pressure range, the KRSA series operates efficiently within a pressure range of 100 to 150 psi, making it ideal for a variety of industrial processes.

- Motor Power: Equipped with high-efficiency motors, the KRSA compressors are available in multiple power ratings to suit different operational scales. Motor power options range from 10 kW to over 300 kW, ensuring optimal energy use for any given air demand.

- Dimensions: The compact design of the KRSA series allows for easy integration into existing operations, with dimensions varying by model to accommodate space constraints.

- Weight: Despite their robust construction, KRSA compressors are designed with manageability in mind, featuring weights that facilitate installation and relocation.

- Portability Features: Select models of the KRSA series include portability features such as built-in wheels and handles, enhancing flexibility and ease of movement within industrial environments.

- Industrial Applications: The KRSA series is versatile enough to serve a broad spectrum of industries, including manufacturing, automotive, construction, and more, providing reliable and efficient compressed air for various low-pressure applications.

- Environmental Conditions: Designed to withstand harsh industrial environments, KRSA compressors operate effectively within a wide range of temperatures and humidity levels, ensuring consistent performance under varying environmental conditions.

Applications and Industries Served

The Kaishan Compressors Australia KRSA Single Stage Low Pressure Rotary Screw Air Compressor is a versatile powerhouse, engineered to meet the diverse needs of multiple sectors. Its robust design and reliable performance make it an ideal choice for a wide range of applications across various industries, including manufacturing, automotive, and construction. This section highlights the compressor’s adaptability, showcases case studies of its application in different industries, and outlines the benefits it brings in terms of productivity and operational efficiency.

MANUFACTURING

MINING

WORKSHOP

FOOD AND BEVERAGE

TIMBER

WATER TREATMENT

FABRICATION

Looking after our environment

Energy Efficiency and Environmental Impact

The Kaishan Compressors Australia KRSA Single Stage Low Pressure Rotary Screw Air Compressor is not only a powerhouse of performance but also a beacon of energy efficiency and environmental stewardship. Understanding the critical importance of sustainability in today’s industrial landscape, the KRSA compressor is engineered to minimize energy consumption while maximizing output, thereby significantly lowering operational costs for businesses.

Energy-Saving Features and Lower Operational Costs

The KRSA compressor incorporates several advanced energy-saving features designed to reduce power usage without compromising on efficiency. Its innovative design ensures that air compression is achieved more effectively, requiring less energy to produce high volumes of compressed air. This efficiency translates directly into lower electricity bills, making the KRSA compressor an economically smart choice for businesses focused on reducing operational expenses.

Environmental Benefits

In an era where environmental consciousness is paramount, the KRSA compressor stands out for its minimal environmental impact. By optimizing energy use, it significantly reduces the carbon footprint of operations that rely on compressed air. This not only helps businesses meet their sustainability goals but also contributes to global efforts to combat climate change. The reduced energy consumption leads to fewer greenhouse gas emissions, making the KRSA compressor an environmentally responsible choice for industries looking to minimize their ecological impact.

Compliance with International Environmental Standards

Kaishan Compressors Australia is committed to not only meeting but exceeding international environmental standards and regulations. The KRSA compressor is designed and manufactured with these standards in mind, ensuring that businesses using this equipment are in full compliance with environmental regulations. This commitment to environmental excellence further underscores the KRSA compressor’s role in promoting sustainable industrial practices.

Installation and Maintenance

Ensuring your Kaishan Compressors Australia KRSA Single Stage Low Pressure Rotary Screw Air Compressor operates at peak efficiency starts with proper installation and continues with diligent maintenance. This guide provides a comprehensive overview of the installation process, routine maintenance tips, and troubleshooting advice to keep your compressor running smoothly.

Step-by-Step guide on the installation process for the KRSA Compressor

- Site Preparation: Choose a well-ventilated area with enough space for operation and maintenance activities. Ensure the floor is level and can support the weight of the compressor.

- Unpacking and Inspection: Carefully unpack the compressor and inspect for any damage that may have occurred during shipping. Report any discrepancies immediately.

- Positioning: Place the compressor in its designated spot, allowing for ample clearance around the unit as specified in the user manual.

- Electrical Connection: Have a licensed electrician connect the compressor to the power supply, adhering to all local codes and regulations.

- Air System Connection: Connect the air output to your facility’s air system. Ensure all connections are secure and leak-free.

- Initial Start-Up: Follow the manufacturer’s instructions for the initial start-up, including checking oil levels and verifying control settings.

Routine maintenance tips to ensure optimal performance and longevity

Regular maintenance is crucial for the long-term reliability and performance of your KRSP compressor. We recommend adhering to a maintenance schedule that includes routine checks and replacements of consumable parts like air filters, oil filters, and separators at prescribed intervals. Regular oil changes, as well as checks on belts and couplings, can prevent unexpected downtime and extend the life of your compressor.

Kaishan Australia offers detailed maintenance schedules tailored to the specific needs of your KRSP compressor, taking into account its operational environment and usage patterns. Following these schedules not only ensures optimal performance but also maximizes the efficiency of your compressor.

Troubleshooting Common Issues and how to address them effectively

- Low Pressure: Check for air leaks in the system, inspect the air filter for clogs, and ensure the intake valve is fully open.

- High Operating Temperature: Clean the radiator, check the oil level, and ensure the environment is adequately ventilated.

- Unusual Noises: Tighten any loose parts, check for worn belts, and ensure the compressor is level.

By following this installation and maintenance guide, you can maximize the efficiency, performance, and lifespan of your Kaishan Compressors Australia KRSA Single Stage Low Pressure Rotary Screw Air Compressor. Regular maintenance not only prevents downtime but also ensures your compressor operates within its environmental and energy efficiency parameters. For more detailed information, consult your KRSA compressor manual or contact our technical support team.