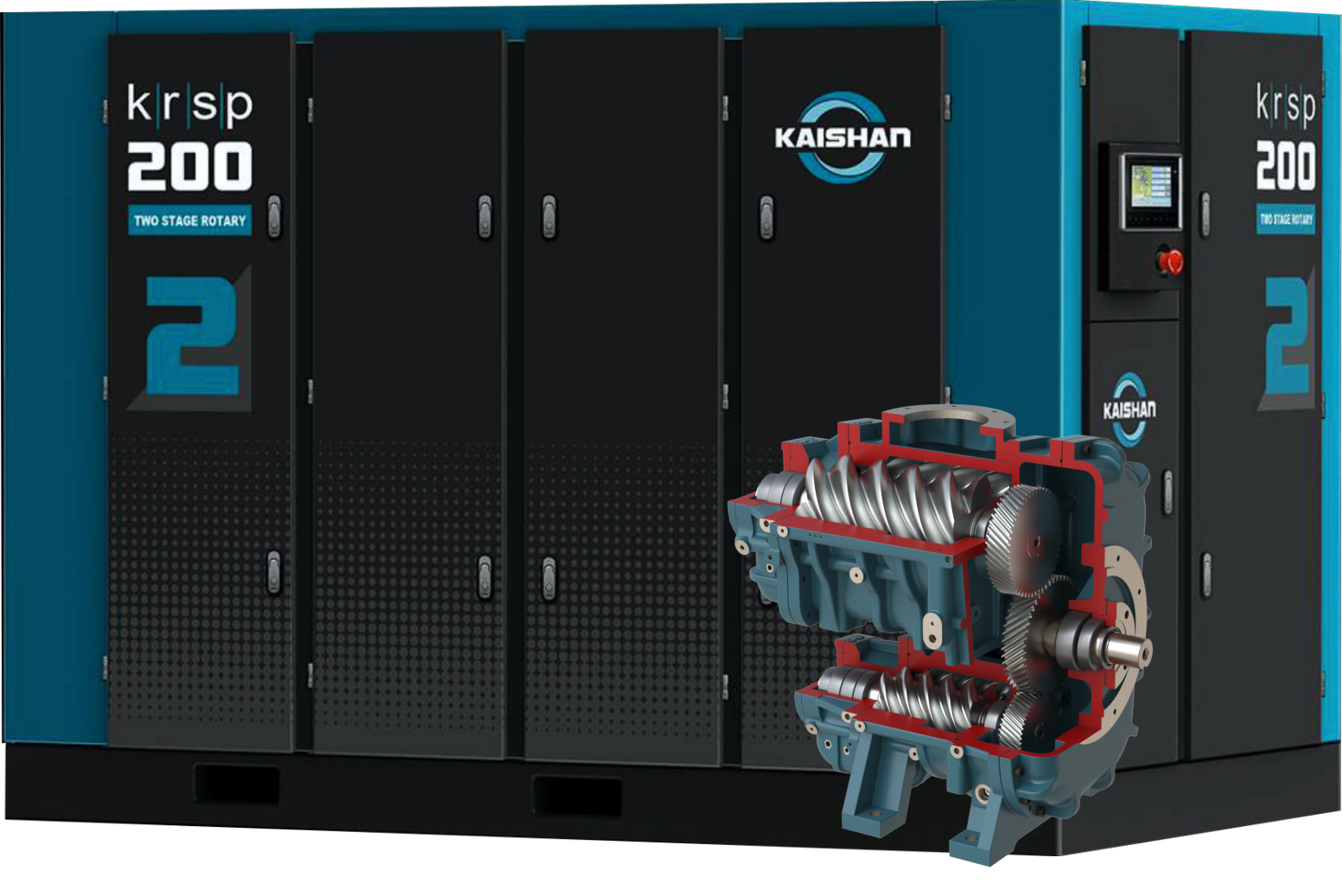

KRSP 2-Stage Rotary Screw Compressor

75kW – 400kW AIR COMPRESSOR

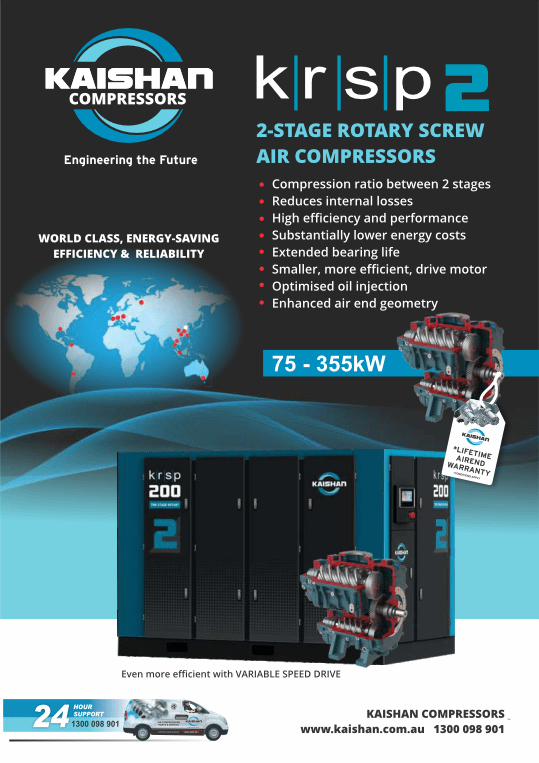

- COMPRESSION RATIO BETWEEN 2 STAGES

- REDUCES INTERNAL LOSSES

- HIGH EFFICIENCY AND PERFORMANCE

- SUBSTANTIALLY LOWER ENERGY COSTS

- EXTENDED BEARING LIFE

- SMALLER, MORE EFFICIENT, DRIVE MOTOR

- OPTIMISED OIL INJECTION

- ENHANCED AIR END GEOMETRY

Kaishan KRSP 2-Stage Industrial Rotary Screw Air Compressors are renowned for their quality engineering, performance, efficiency, and energy-saving technologies, serving as the backbone for major industries globally. As a leader in rotary screw compressor technology, Kaishan continuously invests in research and development to maintain its position at the forefront of compressed air innovation.

Welcome to the forefront of air compression technology with the KRSP 2-Stage Air Compressor, a hallmark of innovation and efficiency brought to you by Kaishan Australia. This cutting-edge air compressor is designed to meet the rigorous demands of various industries, offering unparalleled performance and reliability.

At the heart of the KRSP 2 Stage Air Compressor is its revolutionary 2-stage compression technology. This advanced system allows for higher efficiency and performance by compressing the air in two stages. The first stage compresses the air to a certain level, and then the second stage further compresses the air to the desired pressure. This process not only enhances the efficiency of the air compressor but also significantly reduces energy consumption and operational costs.

Kaishan Australia is at the forefront of the air compressor industry, consistently pushing the boundaries of what’s possible with air compression technology. The KRSP 2 Stage Air Compressor is a testament to our commitment to innovation, quality, and performance. By choosing Kaishan Australia, you’re not just getting an air compressor; you’re investing in a solution that will drive your business forward with unmatched efficiency and reliability.

Stay ahead of the curve with the KRSP 2-Stage Air Compressor from Kaishan Australia, where innovation meets performance-

WHAT'S INSIDE THE KAISHAN AUSTRALIA 2-STAGE KRSP AIR COMPRESSOR

'SKY' Series Airend

Triple Discharge Bearings (45kW and above)

Advanced Digital Control Panel

Centrifugal Cooling Fans

Single Pass Oil and After Coolers

Integrated Dryer/Air Filter

Ultra Web Air Intake Filters

Three Stage Tangential Oil Separation

High Efficiency

Electric Motor

- Maximum Output with Less Energy Usage

- Asymmetric 5 / 6 rotor profile with 100% SKF bearings

- KAPP Ground rotor technology for tighter clearances efficiency and performance

- Precision machined bell housing to maintain rigid alignment

Asymmetric 5/6 rotor profile

KAPP ground rotor technology for tighter clearances and improved lubrication

Low noise and vibration

SKF bearings

Monitors & Controls Key Compressor Functions

• Protects compressor in the event of a fault

• Provides service required alert

• Sequencing of up to 16 compressors

• External monitoring via RS 485 interface

• WYE Delta starter is standard on all non VSD models

• MODBUS interface

• Higher static pressure allows for energy saving heat recovery

• Even air flow across the cooler face.

• VSD cooling fan (110kW and above) provides energy savings as cooling airflow is reduced during low temperatures. periods of light load or compartment resulting

• Cooling air bypasses main compressor dust build up in minimal internal

Long Life / Easily Accessible

• Minimise thermal stress

• Cooler running temperatures / correct running ambient capable

• Low cooling air velocity reduces dustbuild up temperature @ 50°C Increased lubricant life • Low oil carryove

Long Tubing Life / Reduced Downtime

• Increased reliability due to corrosion free material

• Material such as nylon, copper or mild steel will fail in time causing downtime

Increased Filtration Efficiency

• Full airflow, low restriction, nanofiber technology

• Deep bed media ensures excellent dust capture

• Increased free air delivery for further savings in energy and running costs

Lower Pressure Drop / Lower Absorbed Power

• Excellent oil mechanical pre-separation/ reduced direct oil separator element

• Lower dust contact resulting in lower pressure drop/longer energy consumption

• Residual oil carryover limited to 3 ppm impingement onto element life/lower Increased lubricant life

Long Operating Life / Lower Power Use

• Kaishan uses high efficiency motors, which comply with MEPS2 requirements

• Motors are TEFC to protect from dust and moisture

• Class F insulation

KEY FEATURES

The KRSP 2-Stage Air Compressor from Kaishan Australia stands out in the market for its exceptional features designed to meet the needs of various industries. Here, we delve into the key features that make this air compressor a must-have for businesses looking for efficiency, durability, and ease of use

![]() Energy-Efficient Operation: At the heart of the KRSP 2-Stage Air Compressor is its energy-efficient operation, made possible by the innovative 2-stage compression process. This process allows for reduced energy consumption by optimising air compression in two phases, significantly lowering operational costs. Businesses focused on sustainability and reducing their carbon footprint will find the KRSP 2-Stage Air Compressor an ideal choice.

Energy-Efficient Operation: At the heart of the KRSP 2-Stage Air Compressor is its energy-efficient operation, made possible by the innovative 2-stage compression process. This process allows for reduced energy consumption by optimising air compression in two phases, significantly lowering operational costs. Businesses focused on sustainability and reducing their carbon footprint will find the KRSP 2-Stage Air Compressor an ideal choice.

![]() Robust Construction and Durability: Durability is a cornerstone of the KRSP 2-Stage Air Compressor’s design. Built to withstand the rigors of continuous use, this air compressor features robust construction that ensures long-term reliability. Whether you’re operating in harsh industrial environments or requiring consistent performance, the KRSP 2-Stage Air Compressor is engineered to last, providing peace of mind.

Robust Construction and Durability: Durability is a cornerstone of the KRSP 2-Stage Air Compressor’s design. Built to withstand the rigors of continuous use, this air compressor features robust construction that ensures long-term reliability. Whether you’re operating in harsh industrial environments or requiring consistent performance, the KRSP 2-Stage Air Compressor is engineered to last, providing peace of mind.

![]() Advanced Control Systems: Ease of operation is another hallmark of the KRSP 2-Stage Air Compressor. Equipped with advanced control systems, this air compressor offers users an intuitive interface for easy operation and monitoring. Analise performance data, the control systems ensure that managing your air compressor is straightforward and efficient. This feature is particularly beneficial for businesses looking to streamline their operations and minimise downtime.

Advanced Control Systems: Ease of operation is another hallmark of the KRSP 2-Stage Air Compressor. Equipped with advanced control systems, this air compressor offers users an intuitive interface for easy operation and monitoring. Analise performance data, the control systems ensure that managing your air compressor is straightforward and efficient. This feature is particularly beneficial for businesses looking to streamline their operations and minimise downtime.

krsp compressors provide high efficiency with low capital cost and low operating cost.

Low cost of ownership throughout life cycle Compressed air is often referred to as the ‘fourth utility’ and is critical to most manufacturing operations. Facility performance depends upon compressor reliability and efficiency. Power consumption is a significant cost throughout the life of a compressor, therefore it is important to consider the life cycle cost of a compressed air system when evaluating productivity improvements. KRSP series advanced energy saving features reduce operational costs significantly.

WORLD CLASS ENGINEERING

INTERNATIONALLY PATENTED ‘SKY’ AIREND DEVELOPED EXCLUSIVELY BY KAISHAN ENGINEERS

Continual trial and development has created an advanced airend that increases compressor efficiency by more than 20% over earlier models.

- 2-Stage airend design for high flow rate and low power consumption

- Direct coupled motor and airend with machined bell housing to maintain alignment for long coupling life

- Low part load energy consumption

Steady system pressure lowers system stress and overall air demand - Slow speed rotors maximise performance and increase reliability

- Decreased energy consumption delivers environmentally friendly savings

- 5/6 rotor profile optimal performance while reducing energy consumption

- 2 in 1 intake valve design (with check valve) for increased efficiency

- Direct flow inlet valve provides reliable capacity control

- Triple discharge bearings on each rotor for durability and reliability

- Very tight tolerances provide maximum efficiency

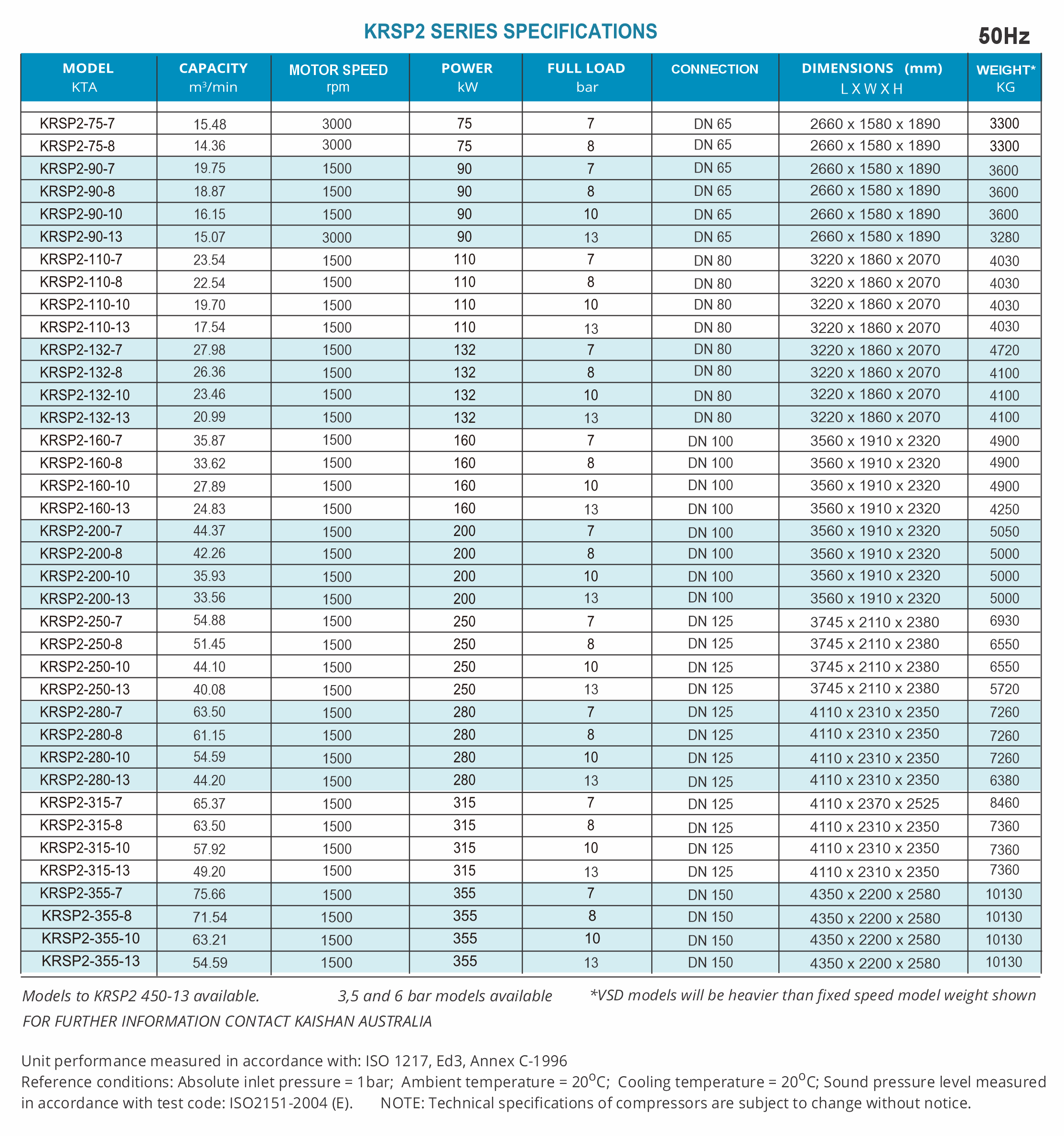

Technical Specifications of 2-Stage KRSP Rotary Screw Compressors

The KRSP 2-Stage Air Compressor from Kaishan Australia is engineered to deliver superior performance and reliability for a wide range of industrial applications. Understanding its technical specifications is crucial for businesses looking to make an informed decision. Below, we detail the key specifications that set the KRSP 2-Stage Air Compressor apart.

The KRSP 2-Stage Air Compressor comes with a robust power range designed to meet diverse operational needs. Whether your application requires low, medium, or high power, our models are equipped to deliver efficiently. The power ratings span from smaller units suitable for larger units designed for heavy-duty operations.

Our compressor boasts impressive pressure capabilities, ensuring that even the most demanding applications can be handled with ease. The KRSP 2-Stage Air Compressor operates efficiently across a broad spectrum of pressure requirements, making it a versatile choice for various industrial settings.

Flow rate is a critical factor in the performance of an air compressor, and the KRSP model excels in this area. Designed to provide consistent and reliable flow rates, it ensures that your operations run smoothly without interruption. The compressor’s flow rates are optimised for efficiency, reducing energy consumption and operational costs.

Applications and Industries Served

The KRSP 2-Stage Air Compressor from Kaishan Australia is a versatile powerhouse, designed to meet the diverse needs of various industries. Its robust design and efficient performance make it an ideal choice for a wide range of applications, from manufacturing plants to automotive workshops. Here, we explore the broad spectrum of applications where the KRSP 2-Stage Air Compressor excels, highlighting its benefits for specific sectors.

MANUFACTURING

MINING

WORKSHOP

FOOD AND BEVERAGE

TIMBER

WATER TREATMENT

FABRICATION

Looking after our environment

In today’s environmentally conscious world, energy efficiency is not just a preference; it’s a necessity. Kaishan Australia is at the forefront of this movement with our KRSP Rotary Screw Compressors, which are designed with cutting-edge energy-saving technologies. One of the standout features of our compressors is the incorporation of variable speed drives (VSD). These drives adjust the motor speed to match the air demand, significantly reducing energy consumption and operational costs. This technology ensures that our compressors are not only efficient but also have a lower environmental impact.

The environmental benefits of using KRSP compressors are substantial. By optimising energy use, these compressors contribute to a significant reduction in carbon emissions. This is crucial for businesses aiming to reduce their carbon footprint and make a positive impact on the environment. Moreover, the reduced energy consumption of KRSP compressors aligns with global efforts to conserve energy resources and combat climate change.

KRSP compressors are designed to help businesses achieve their sustainability goals. They are engineered to comply with the most stringent environmental regulations, ensuring that your operations are not only efficient but also environmentally responsible. By choosing KRSP compressors, you are not just investing in a high-quality air system; you are also contributing to a sustainable future.

In summary, the energy efficiency and environmental benefits of KRSP Rotary Screw Compressors make them an ideal choice for businesses committed to sustainability and regulatory compliance. With advanced technologies like variable speed drives, these compressors offer a way to reduce energy consumption, lower carbon emissions, and achieve environmental goals without compromising on performance.

Installation and Maintenance

Ensuring your KRSP 2-Stage Air Compressor operates at peak performance involves proper installation and regular maintenance. This guide provides step-by-step instructions for installation, routine maintenance tips, and troubleshooting common issues to help you get the most out of your compressor.

Step-by-Step Installation Instructions for Optimal Performance

- Location Selection: Choose a clean, dry, and well-ventilated area for your compressor. Ensure there’s enough space around the unit for easy maintenance access.

- Electrical Connection: Connect the compressor to a power supply that matches the specifications listed in the manual. It’s highly recommended to use a dedicated circuit to prevent power fluctuations.

- Air System Connection: Attach the air intake and outlet hoses. Ensure all connections are tight and secure to prevent leaks.

- Test Run: Before full operation, perform a test run to check for any irregularities. Listen for unusual noises and check for leaks.

Routine Maintenance Tips to Ensure Longevity and Efficiency

- Daily: Check the oil level and drain any condensate from the tanks.

- Weekly: Inspect hoses and connections for leaks or wear. Clean the air filter to prevent dust build-up.

- Monthly: Check the belt tension and adjust as necessary. Inspect the safety release valve to ensure it’s functioning correctly.

- Annually: Replace the air filter and oil. Have a professional service the compressor to check for any internal wear or issues.

Troubleshooting Common Issues and How to Address Them

- Compressor Not Starting: Check the power supply and fuses.

- Loss of Pressure: Inspect hoses and connections for leaks. Check the integrity of the air tank and ensure the valves are sealing properly.

- Excessive Noise or Vibration: Tighten any loose parts. Ensure the compressor is on a stable, level surface.

- Overheating: Check that cooler is clean and clear of debris – remove and clean the Air filter. Ensure the compressor is in a well-ventilated area and not overloaded.

Benefits of Choosing the Kaishan Australia 2 -Stage KRSP Air Compressor

Choosing the KRSP 2-Stage Air Compressor from Kaishan Australia brings a multitude of benefits to your industrial operations, setting a new standard in efficiency and reliability. Here’s why making this choice is a smart move for your business:

The KRSP 2-Stage Air Compressor is engineered for optimal efficiency, offering significant energy savings that directly translate to reduced operational costs. Its innovative design ensures that you get the maximum output for the minimum input, making it an economical choice for businesses looking to optimise their energy consumption and lower their utility bills. This compressor is designed to operate at peak efficiency, even under demanding conditions, ensuring that you save on energy without compromising on performance.

Designed with demanding industrial applications in mind, the KRSP 2-Stage Air Compressor delivers enhanced performance and unmatched reliability. Its robust construction and advanced engineering ensure that it can handle continuous operation in even the most challenging environments. Whether you’re in manufacturing, automotive, or any other industry requiring reliable compressed air, this compressor is built to meet your needs, ensuring uninterrupted operations and maximum productivity.

One of the standout benefits of the KRSP 2-Stage Air Compressor is its long service life, coupled with minimal maintenance requirements. This compressor is built to last, using high-quality materials and components that withstand the test of time. Its design not only ensures durability but also makes maintenance tasks straightforward and infrequent. This means less downtime for maintenance and more time focusing on what matters most – your business operations.