- Large capacity, slow running SKK airend

- 500 litre, AS1210 approved receiver

- Integrated aftercooler

- Integrated dryer and air filter

- Large air intake filtration

- Full function digital control panel

- Automatic belt tensioning

- MEPS II compliant drive motor

Compact Rotary Screw Air Compressor

4kW– 22kW

0.33 – 3.4 m3/min (12-120cfm) 8 – 13 bar

Kaishan KRST compact Rotary Screw Air Compressor series are the ideal package for industries requiring high performance from a small footprint compressed air unit. These compressors are designed to be easily installed whilst producing maximum output with outstanding reliability.

Engineered from the highest quality components, utilising the latest in compressed air technology, every compressor is mounted on a 500 litre air receiver with an 3°C pressure dewpoint refrigerated dryer and coalescing filter to produce outstanding air quality. The Kaishan KRST range offers capacities from 0.55 m³/min to 2.35 m³/min and are suited to a diverse range of applications.

DOWNLOAD BROCHURE HERE

click image

Discover the KRST Compact Rotary Screw Air Compressor by Kaishan Australia

Welcome to Kaishan Australia, where our dedication to engineering excellence and innovation sets us apart in the compressed air industry. With a steadfast commitment to providing high-quality air compressors, we are proud to introduce the KRST Tank Mounted Air Compressor series, a testament to our relentless pursuit of efficiency and reliability in compressed air solutions.

The Kaishan KRST Series of receiver mounted rotary screw air compressors represents the pinnacle of compact, high-performance compressed air solutions ideal for various industrial applications. These rotary screw compressors are meticulously designed to deliver maximum output while ensuring outstanding reliability and minimizing energy consumption.

Crafted with the finest components and leveraging advanced rotary screw technology, the Kaishan KRSP range provides a spectrum of capacities from 0.55 m³/min to 2.35 m³/min, catering to a wide array of industrial needs. Each unit undergoes extensive testing to adhere to both rigorous Australian and international quality standards, ensuring top-tier performance and durability.

Supported by Kaishan Australia’s comprehensive service network, these rotary screw air compressors are not only built to perform but are also backed by reliable customer and technical support. Whether you’re in manufacturing, automotive, or any sector requiring dependable compressed air, the Kaishan KRST and KRSP series offer the solutions you need to enhance efficiency and productivity.

WHAT'S INSIDE the KRST Tank Mounted Air Compressor

KEY FEATURES

500 Litre

Air Receiver

Large Air End

Integrated Dryer/

Air Filter

High Efficiency

Drive Motor

Digital Control Panel

Automatic

Belt Tightener

Integrated Air Cooling/Cooling Fan

Large Cyclonic

Air Intake

Filtration

Reduced load cycles for minimum energy consumption Reduced wear and tear on control system Peak demand coverage Increased condensate removal AS1210-3 approval

Large, slow running airend

Asymmetric 5/6 rotor profile

KAPP ground rotor technology for tighter clearances and improved lubrication

Low noise and vibration SKF bearings

High efficiency Increased reliability and lifespan

Minimised footprint

0.5 micron pre-filter

Auto condensate drain

3ºC pressure dewpoint

MEPS ll compliant

TEFC to IP55 protection against dust and moisture

Class F insulation

Precise monitoring of key functions

Fault detection and protection

Service due alert

Star-Delta starter to reduce current demand during start-up

Extended belt life

Minimised bearing loads

Reduced energy consumption

No adjustments required

Efficient cooling for high ambient conditions

10ºC approach temperature •

Minimal pressure drop for increased efficiency

High level contaminant removal

Long element life

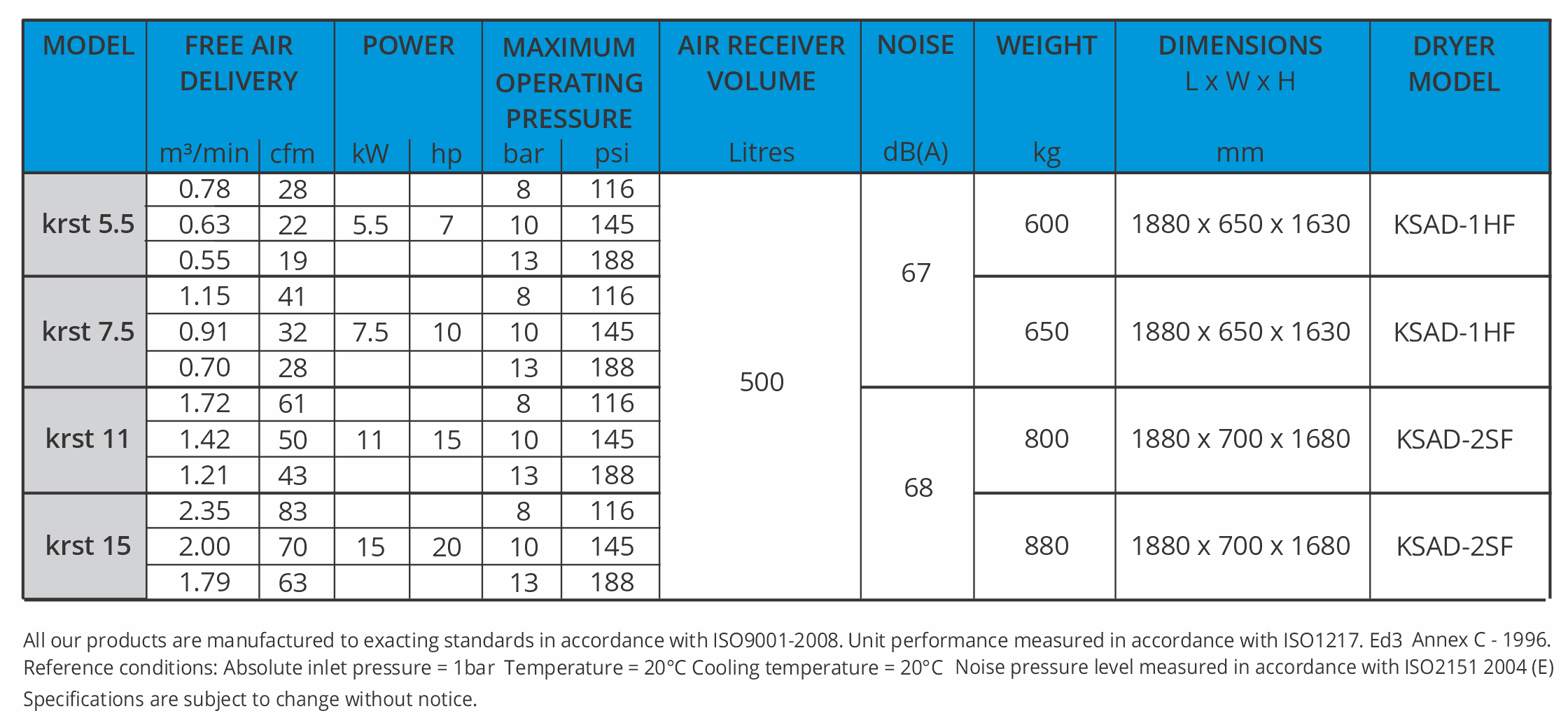

Specification Table

The Kaishan Australia KRST Tank Mounted Air Compressor is engineered with a suite of features designed to meet the demanding needs of modern industries. At the heart of its design philosophy is the commitment to delivering not just air, but efficiency, reliability, and performance. Here are the key features that set the KRST series apart:

DOWNLOAD BROCHURE HERE

click image

Technical Specifications of KRST Tank Mounted Air Compressors

The KRST Series from Kaishan Australia represents the pinnacle of tank mounted air compressor technology, designed to meet the diverse needs of modern industries. This section delves into the technical specifications, the innovative technology behind the series, and a comparative analysis to underscore the KRST’s superior performance.

The KRST Series is engineered to cater to a wide array of applications, offering a power range that spans from 7.5 kW to 15 kW. This versatility ensures that whether your operation is small, medium, or large, there’s a KRST model that fits your requirements perfectly. The pressure ratings are equally impressive, with options available from 8 bar up to 13 bar. This range guarantees that you can find the right pressure setting for your specific compressed air needs, ensuring efficiency and reliability.

Capacity is a critical factor in choosing an air compressor, and the KRST Series excels in this area. With air delivery volumes ranging from 0.85 m³/min to 2.35 m³/min, these compressors are designed to sustain a wide variety of pneumatic tools and processes. This capacity range underscores the KRST’s adaptability to different industrial environments, ensuring that your operations run smoothly without interruption.

At the heart of the KRST Series’ superior performance is Kaishan’s advanced screw technology, which provides higher efficiency and lower energy consumption compared to traditional compressors. This technology ensures that the KRST Series compressors deliver consistent, high-quality compressed air with less wear and tear, translating into longer service life and reduced maintenance costs. Additionally, the integrated design combines the air compressor, dryer, and air tank in a single unit, saving valuable floor space and simplifying installation.

When compared to other models in the market, the KRST Series stands out for its efficiency, reliability, and cost-effectiveness. Its advanced screw technology not only offers better performance but also ensures that the compressors operate more quietly and with less vibration. Furthermore, the integrated design of the KRST Series reduces the need for additional components, making it a more economical and convenient solution for businesses looking to optimize their compressed air systems.

Applications and Industries Served

The Kaishan Australia KRST Tank Mounted Air Compressor is a versatile and powerful solution designed to meet the diverse needs of various industries. Its robust design and efficient performance make it an ideal choice for a wide range of applications, ensuring that businesses across different sectors can benefit from its reliability and efficiency. Below, we explore some of the key industries and applications where the KRST series excels.

MANUFACTURING

MINING

WORKSHOP

FOOD AND BEVERAGE

TIMBER

WATER TREATMENT

FABRICATION

Installation and Maintenance

Ensuring your Kaishan Australia KRST Tank Mounted Air Compressor operates at peak efficiency starts with proper installation and continues with diligent maintenance. This guide provides a step-by-step overview of the installation process, maintenance schedule, and troubleshooting tips to help you maximize the performance and reliability of your KRST series compressor.

Step-by-Step Installation Process

- Location Selection: Choose a clean, dry, and well-ventilated area for your compressor. Ensure there’s enough space around the unit for easy maintenance access.

- Unpacking and Inspection: Carefully unpack your KRST compressor and inspect it for any damage that may have occurred during shipping. Report any issues immediately.

- Electrical Connection: Connect the compressor to a power supply following local electrical codes. It’s highly recommended to use a certified electrician for this step.

- Air System Connection: Attach your air distribution system to the compressor, ensuring all connections are secure and leak-free.

- Initial Start-Up: Before the first start-up, check all fittings and connections. Then, follow the manufacturer’s instructions to power on the compressor for the first time.

Maintenance Tips and Schedules

- Daily: Check for any leaks or unusual noises. Monitor pressure levels and temperature for any irregularities. Drain Condensate, check oil (change annually when due)

- Weekly: Drain any condensate from the tank, and inspect hoses and connections for wear or damage.

- Monthly: Replace or clean air filters as needed. Check the oil level and top up if necessary.

- Annually: Schedule a professional inspection and maintenance service. This should include checking the motor, electrical connections, and performing any necessary adjustments or replacements.

Troubleshooting Common Issues

- Compressor Not Starting: Check the power supply, fuses, and any emergency stop buttons. Ensure the pressure switch is functioning correctly.

- Low Air Pressure: Inspect for leaks in the air system. Check if the air intake filter is clogged and replace it if necessary.

- Excessive Noise or Vibration: Tighten any loose parts and mounts. Check for worn belts and replace them as needed.

- Overheating: Ensure the compressor is in a well-ventilated area.

Benefits of choosing Kaishan KRST Air Compressors

When it comes to selecting an air compressor for your business, the Kaishan KRST Tank Mounted Air Compressor stands out for its exceptional benefits. Designed with your needs in mind, this compressor offers a blend of reliability, efficiency, and versatility that is hard to match. Here’s why choosing the Kaishan KRST series can be a game-changer for your operations:

The Kaishan KRST Air Compressors are engineered for longevity. Built with high-quality materials and cutting-edge technology, these compressors are designed to withstand the rigors of daily use, ensuring long-term reliability and durability. This robust construction not only extends the life of the compressor but also significantly reduces maintenance costs. With less downtime and fewer repairs, your operations can continue smoothly, enhancing productivity and profitability.

In today’s eco-conscious business environment, energy efficiency is not just a preference but a necessity. The KRST series is at the forefront of energy-saving technology. Its innovative design minimises energy consumption, leading to substantial savings on operational expenses. By choosing Kaishan KRST Air Compressors, you’re not just investing in a high-performance tool; you’re also opting for a solution that lowers your energy bills and supports your sustainability goals.

Flexibility is key in dynamic industrial environments, and the Kaishan KRST series excels in this aspect. Whether you’re in manufacturing, automotive, construction, or any other industry, these compressors are equipped to meet a wide range of applications. Thanks to their adaptable features and specifications, you can easily integrate them into your existing systems, regardless of the specific requirements of your operations. This versatility ensures that, no matter the task, the KRST series is up to the challenge.